The Evolution of Ziplock Technology: Innovations Shaping the Future of Flexible Packaging

Frustrated with zippers that break or don’t seal properly? Old ziplock technology can lead to spoiled products and unhappy customers, damaging your brand’s reputation. It’s time for an upgrade.

Ziplock technology is evolving rapidly with innovations in materials, design, and functionality. These advancements offer enhanced user experience, better product protection, and more sustainable options for flexible packaging across various industries.

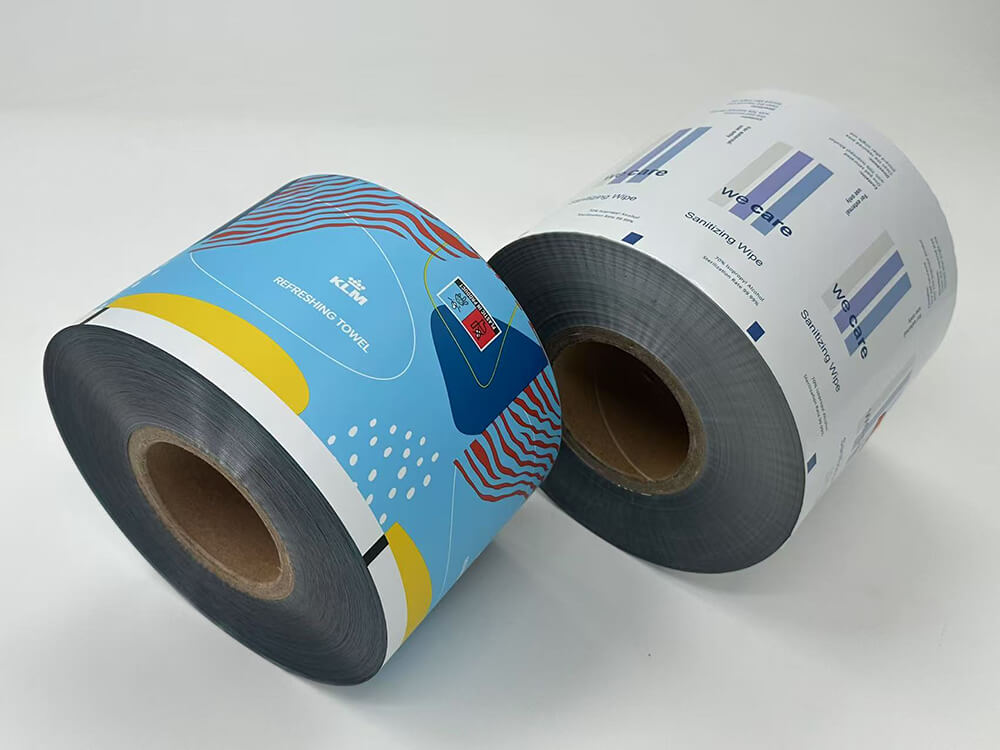

As a ghostwriter for Noupack, a flexible packaging manufacturer, I’ve seen firsthand how crucial a good resealable feature is. Our clients, who produce everything from snacks and coffee to specialized items like alcohol pads (which Stuart in South Africa wraps using our film rolls), all recognize that a reliable closure system significantly impacts consumer satisfaction and product integrity. The simple ziplock has come a long way from its early days. It’s no longer just about closing a bag; it’s about enhancing convenience, preserving freshness, and even contributing to a brand’s image. Let’s explore how these innovations are changing the game.

How Do Different Sectors Leverage Ziplock Packaging Effectively?

Is a one-size-fits-all ziplock approach hindering your product’s potential? Different products have unique protection and convenience needs that generic resealable features cannot adequately address, leading to compromised quality.

Sectors like food use ziplocks for freshness and portion control, pharmaceuticals for child safety and tamper evidence, and industrial applications for secure containment and reusability of small parts, tailoring features accordingly.

What Eco-Friendly Innovations Are Emerging in Resealable Packaging Materials, Design, and Disposal?

Is the environmental impact of traditional plastic zippers a concern for your brand? Conventional zippers can hinder recyclability and contribute to plastic waste, clashing with growing consumer demand for sustainable solutions.

Eco-friendly innovations include zippers made from the same mono-material as the pouch (e.g., PE zippers on PE pouches for easier recycling), compostable zippers, and designs that facilitate easy separation of components.

Greening the Seal: Sustainable Zippers

Sustainability is a huge driver in packaging innovation, and zippers are no exception. At Noupack, we are committed to providing more environmentally friendly materials, and that extends to the resealable features we offer.

- Mono-Material Zippers: One of the biggest breakthroughs is the development of zippers made from the same material as the pouch film, most commonly Polyethylene (PE). A PE zipper on a PE pouch creates a mono-material package that is much easier to recycle through existing PE film recycling streams. This avoids the contamination issues that can arise when different plastics are mixed. We are seeing increasing demand for this, especially from clients in Europe and North America.

- Compostable Zippers: For products packaged in compostable films (like those made from PLA or PHA), compostable zippers are emerging. These are designed to break down along with the rest of the package in industrial or home composting conditions, depending on the specific material. The challenge here is ensuring the zipper provides adequate sealing strength and durability while still meeting compostability standards.

- Design for Recyclability: Beyond the material itself, zipper design can influence recyclability. For example, making zippers easy to separate from the main pouch body (if they are made of a different material) could be a strategy in some cases, though mono-material is generally preferred.

- Recycled Content in Zippers: Just like with films, there’s ongoing research into incorporating post-consumer recycled (PCR) content into the zippers themselves, further closing the loop.

The economic consideration here is that while some of these eco-friendly zipper options might currently have a slight cost premium, the long-term benefits in terms of brand reputation, consumer preference, and meeting regulatory requirements (like upcoming EPR schemes) often outweigh this. For a B2B wholesale supplier like us, offering these sustainable options is becoming essential.

How Are Ziplock Pouches Assessed for Quality: What Testing Methods and Performance Standards Are Used?

Are your ziplock pouches failing prematurely, leading to customer complaints and product spoilage? Inconsistent zipper quality can undermine your brand’s reliability and result in costly issues.

Quality assessment involves rigorous testing for seal strength, repeated open/close cycle durability, leak resistance (air and liquid), particle ingress prevention, and ease of use, often benchmarked against industry or internal standards.

Ensuring a Reliable Seal, Every Time

A ziplock is only as good as its ability to perform consistently. At Noupack, with our 2 inspection machines and commitment to superior quality, we understand that thorough testing is crucial. When we manufacture pouches with zippers for snacks, coffee, or any other product, quality control is paramount.

- Seal Strength (Interlock Strength): This measures how much force is required to pull the closed zipper tracks apart. Specialized equipment applies a controlled force to test the integrity of the interlock. A weak interlock means the zipper can pop open unintentionally.

- Repeated Open/Close Cycle Testing: Zippers need to withstand being opened and closed multiple times without losing their sealing capability or breaking. Automated machines can cycle a zipper hundreds or even thousands of times, after which its performance is re-evaluated.

- Leak Resistance (Air/Liquid): For many products, an airtight or watertight seal is essential. Pouches can be filled with air and submerged in water to check for bubbles (indicating leaks). Alternatively, internal pressure tests can be conducted. For liquid products, specific liquid leak tests are performed.

- Particle Ingress Testing: Especially for powder-proof zippers, tests are done to see if fine particles can get into the zipper mechanism or bypass the seal, which could compromise the product or the zipper’s function.

- Ease of Use and Alignment: While more subjective, assessments are made on how easily the zipper aligns and closes. This can involve user panels or specific force measurements for slider operation.

- Material Integrity: The zipper material itself is checked for defects, proper extrusion, and consistent dimensions.

Performance standards are often set based on the intended application, industry norms (e.g., ASTM standards might provide guidelines), or specific client requirements. For our client Stuart, who values consistency, knowing that the resealable features on any packaging we provide have undergone such testing would be a key assurance.

Conclusion

Our company is dedicated to designing ergonomic ziplock bags and researching innovative material science to design and manufacture better quality ziplock bags for our customers.