Shaped Pouch Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Shaped Pouch achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

The Application Of Shaped Pouch

1. Food and Beverage:

Snacks and Confectionery: Shaped like characters, animals, or the product itself, enhancing appeal, especially for children.

Beverages: Pouches molded into the form of bottles, fruits, or with ergonomic grips. Spouted shaped pouches are popular for juices, smoothies, and sauces.

Pet Food and Treats: Bags shaped like bones, paws, or animals to attract pet owners.

Dairy and Yogurt: Stand-up shaped pouches with spouts for on-the-go consumption.

2. Cosmetic and Personal Care:

Sample Packaging: Uniquely shaped sachets for lotions, creams, and shampoos to create a memorable brand experience.

Single-Use Masks: Pouches shaped to reflect facial contours or with eye-catching designs.

3. Household and Industrial:

Detergents and Cleaners: Shaped pouches with handles or spouts for convenient use and storage.

Automotive Fluids: Durable shaped pouches designed for easy pouring.

Garden Products: Pouches shaped like leaves or tools for fertilizers or plant food.

What Is Shaped Pouch

Shape Customization: Unlike regular rectangular or square pouches, shaped pouches can be manufactured into a variety of shapes, such as circles, ovals, animal figures, or the shape of the product itself. This customization is achieved through the use of specialized molds and die – cutting processes.

Function – specific Design: They often incorporate functional elements like spouts for easy pouring, zippers for re – sealing, handles for convenient carrying, or tear – notches for easy opening. These features enhance the usability and convenience of the packaging.

Laminated Films: Typically, shaped pouches are made from laminated materials. This usually includes a combination of different plastic films, such as polyethylene terephthalate (PET) for strength and good printability, polyethylene (PE) for flexibility and heat – sealability, and sometimes aluminum foil for added barrier protection against moisture, oxygen, and light. This multi – layer structure helps to preserve the quality and freshness of the packaged product.

Co – Extruded Films: Another type of material used is co – extruded films, which are made by combining different polymers during the extrusion process. These films offer excellent barrier properties and can be customized to meet specific product requirements. Some co – extruded films are also designed to be biodegradable or compostable, addressing the growing demand for sustainable packaging solutions.

Key Features Of Shaped Pouch

Customizable Shape: The most distinctive feature is their ability to be molded into a wide variety of shapes, which can be tailored to the specific product or brand. This includes shapes that mimic the product itself, such as a fruit – shaped pouch for fruit – flavored snacks, or shapes that are associated with the brand’s identity, like a logo – inspired pouch. This customization helps products stand out on store shelves and attract consumer attention.

Enhanced Visual Appeal: Shaped pouches often have vibrant and high – quality graphics printed on them. The unique shape, combined with eye – catching designs and colors, creates a visually striking packaging that can significantly increase the product’s marketability. Brands can use this feature to communicate their brand values, product benefits, and key selling points effectively.

Functionality: They can be equipped with various functional features to improve user convenience. Common examples include spouts for easy pouring, which are ideal for liquid or semi – liquid products like juices, sauces, and creams; zippers or re – sealable closures to keep the product fresh after opening, suitable for snacks, dry food, and some personal care items; and handles for easy carrying, making them convenient for on – the – go products such as energy drinks or travel – sized toiletries.

Good Barrier Properties: Shaped pouches are typically made from laminated or co – extruded films that provide excellent barrier protection. They can effectively block moisture, oxygen, light, and odors, helping to preserve the quality and freshness of the packaged product. This is crucial for perishable items like food, beverages, and certain cosmetics.

Contact us to discuss your Shaped Pouch solutions!

We’d like to bring value and save cost for your shaped pouch.

Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Film Packaging?

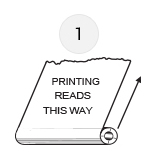

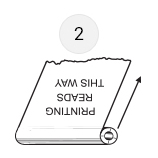

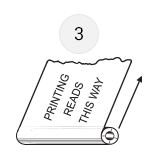

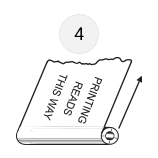

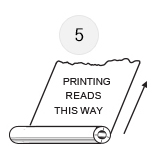

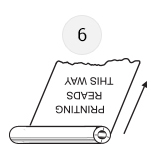

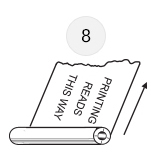

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed flexible packaging roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Shape Pouch and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

CPP (Cast Polypropylene)

Polyethylene (PE)

What is a shaped pouch?

What are some common shapes for shaped pouches?

What are the advantages of shaped pouches compared to traditional packaging bags?

Which industries commonly use shaped pouches?

Are the materials for shaped pouches the same as those for ordinary packaging bags?

Can shaped pouches have zippers or spouts?

What is the printing effect on shaped pouches?

Is the cost of shaped pouches higher than that of ordinary packaging bags?

Are shaped pouches more attractive on shelves?

Are shaped pouches suitable for all types of products?

What is the typical minimum order quantity for shaped pouches?

How long does it take to customize a shaped pouch?

Are there any size limitations for shaped pouches?

Can shaped pouches be made recyclable?

How is the sealing performance of shaped pouches?

Are shaped pouches easily damaged during transportation?

Can shaped pouches be used for liquid products?

What aspects need attention when designing shaped pouches?

What is the future development trend of shaped pouches?

Is my product suitable for shaped pouches? Can you provide advice?

Frequently Asked Questions

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your shaped pouch.