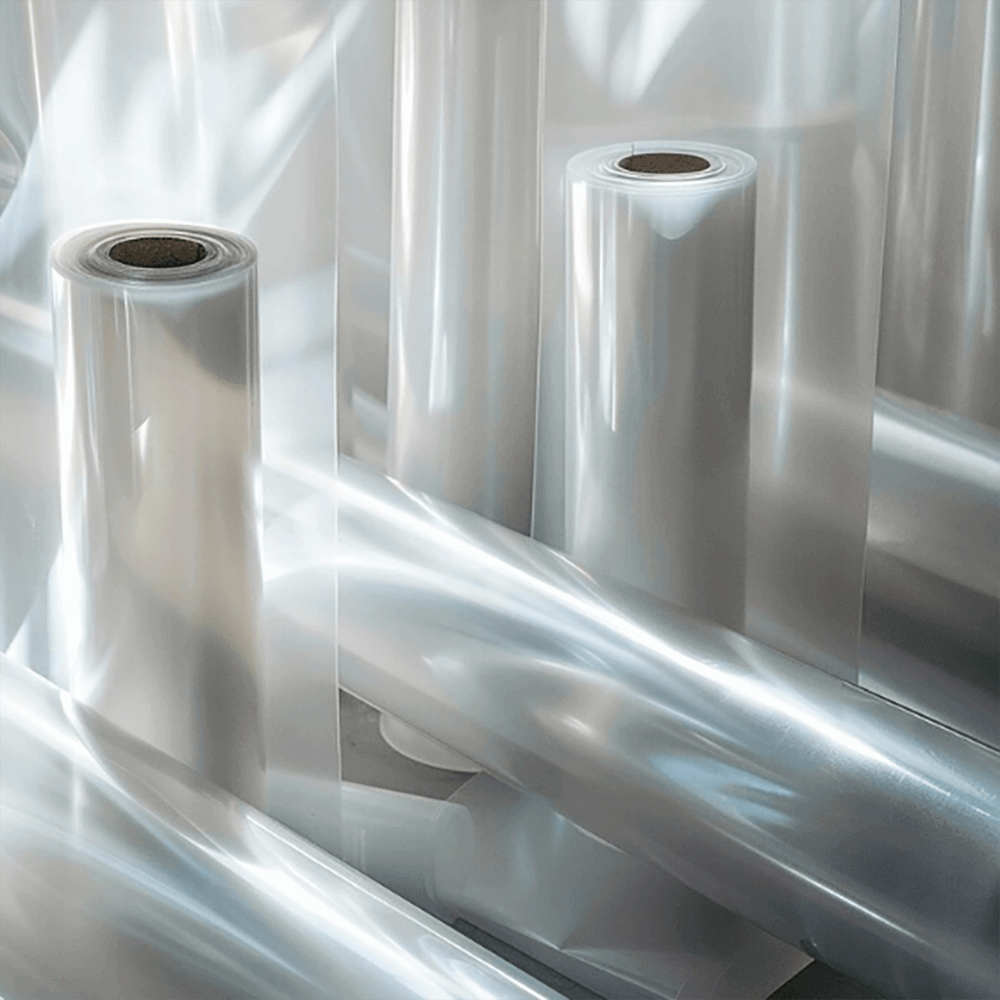

PE film is the largest amount of plastic packaging film, accounting for more than 40% of the total consumption of plastic packaging film.PE film, although the appearance, strength and other aspects is not very ideal, but it has good toughness, moisture resistance and heat sealing properties, and easy to process and molding, inexpensive, so the application is very wide.

(1) Low density polyethylene film.

lDPE film is mainly produced by extrusion blow molding method and t-molding method, in which extrusion blow molding method is more widely used. lDPE blow molding film has better transparency, strength and low cost, so it is widely used. t-molding method produces ldpe film with good appearance and transparency, high strength, but its price is also higher. Ordinary LDPE film is a soft and transparent film, non-toxic, odorless, thickness is generally between 0.02 ~ 0.1mm. It has good water resistance, moisture resistance, cold resistance and chemical stability.

A large number of food, medicine, daily necessities and metal products for general moisture-proof packaging and frozen food packaging. But for moisture absorption, moisture resistance requirements of higher items, it is necessary to use better moisture resistance of the film and composite film packaging.LDPE film permeability is large, no aroma, and oil resistance is poor, can not be used for easy oxidation of food, flavor food and oil-containing food packaging. But good air permeability so that it can be used for fruits, vegetables and other fresh items of fresh packaging.LDPE film heat adhesion and low-temperature heat sealing is good, so commonly used as a composite film adhesive layer and heat sealing layer, etc., but because of its heat resistance is poor, so it can not be used as a cooking bag heat sealing layer.

LDPE can be made into heat shrinkable film using the bubble tube method of stretching process. Its heat shrinkage rate of up to 30% to 35%, and is not easy to break, widely used in the collection of bottles packaging, food cans, beverage bottles tray shrink packaging or “liner collection” packaging. With higher molecular weight LDPE or general film grade LDPE and LLDPE blending, can be produced with a thickness of 0.2 ~ 0.35mm heavy packaging film. Compared with ordinary LDPE film, it has thick film, high strength, especially high tear strength, cracks are not easy to continue to expand and other characteristics.

Therefore, it can be used as fertilizers, pesticides, chemical products and other heavy-duty bags. LDPE can be extruded with HDPE composite blow molding method into a rough outer surface, the inner surface of the smooth heavy packaging anti-slip film. The bags have the effect of anti-slip when stacking, which is convenient for transportation and stacking. In addition, LDPE can also be extruded composite method is the center of the bubble sandwich film material, also known as air cushion film. As the air cushion film is full of air bubbles in the middle, so elastic, with cushioning properties. Can be used as instruments, electronic products, ceramics, glassware and other fragile items cushioning shockproof packaging.

(2) High-density polyethylene film.

Hdpe film is a tough translucent film, its appearance is milky white, poor surface gloss, it is mainly used in extrusion blow molding method of production. Hdpe film tensile strength, moisture resistance, heat resistance, oil resistance and chemical stability are better than the ldpe film, can also be heat-sealed, but not as transparent as ldpe. hdpe can be made into 0.01mm thickness, micro-thin film, its thickness of 0.01mm, its oil resistance and chemical stability is better than that of the ldpe film, can also heat-seal, but not as transparent as ldpe. Hdpe can be made into 0.01mm thickness.

HDPE can be made into micro-thin film with a thickness of 0.01mm, its appearance is very similar to thin silk paper, comfortable feel, also known as paper film. It has good strength, toughness and openness, in order to enhance the sense of paper and reduce costs, can be added to a small amount of lightweight calcium carbonate.HDPE paper film is mainly used to make a variety of shopping bags, garbage bags, fruit bags and a variety of food bags, etc. Because of its poor airtightness, not as good as LDPE. Because of its poor airtightness, does not have the fragrance, so the storage period of packaged food is not long. In addition, HDPE film due to good heat resistance, can be used as a steaming bag heat sealing layer.

(3) Linear low-density polyethylene film.

LLDPE film is the recent development of new varieties of polyethylene film, which is mainly produced by extrusion blow molding method. Compared with LDPE film, LLDPE film has higher tensile and impact strength, tear strength and puncture resistance. In the case of LDPE film with the same strength and performance, the thickness of LLDPE film can be reduced to 20% to 25% of the LDPE film, thus significantly reducing costs. Even if used as heavy bags its thickness is only 0.1mm to meet the requirements, can replace the more expensive high molecular weight high density polyethylene.

Therefore, LLDPE is very suitable for making ultra-thin film, its thickness can be as small as 0.004mm. LLDPE film applications are extremely wide, can be used for a variety of daily necessities packaging, frozen food packaging, but also used in large quantities as heavy bags and garbage bags. LLDPE can also be used as a modifier, which is blended with LDPE or HDPE film made of good durability, puncture resistance, heat resistance, Heat sealability and printability are improved.