Flexible Packaging Solutions

Sustainable flexible packaging solutions such as film rolls, rollstock, pouches & bags...

Flexible Packaging Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Flexible packaging achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

What Is Flexible Packaging

Flexible packaging refers to a type of packaging made from non-rigid materials that can easily change shape, allowing for a versatile and efficient way to package products.

Flexible packaging encompasses any packaging that can be molded, folded, or shaped to fit the product it contains. This includes materials such as plastic films, paper, aluminum foil, and combinations of these materials. Common forms include bags, pouches, wraps, and liners.

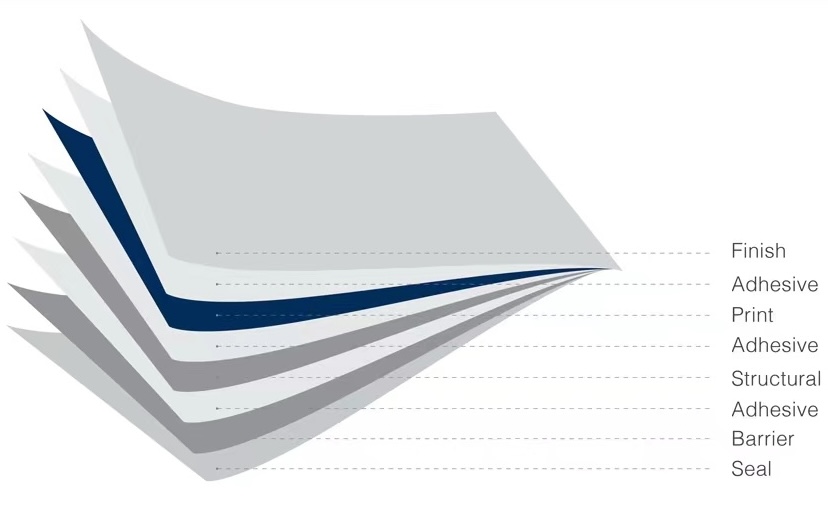

Key Features Of Flexible Packaging

Non-Rigid Materials: Unlike rigid packaging (e.g., glass or metal), flexible packaging uses materials that allow for easy manipulation and adaptation to various product shapes.

Barrier Protection: Flexible packaging often includes barrier layers that protect products from moisture, light, oxygen, and other environmental factors, which helps extend shelf life.

Lightweight: Flexible packaging is generally lighter than rigid alternatives, reducing transportation costs and environmental impact.

Contact us to discuss your flexo packaging solutions!

We’d like to bring value and save cost for your flexible packaging.

Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Film Packaging?

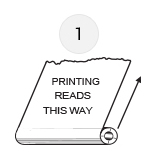

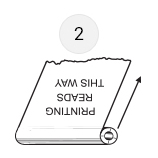

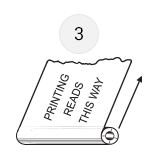

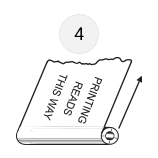

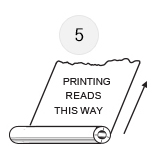

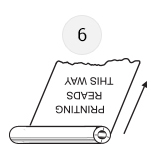

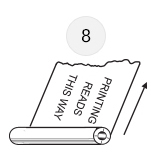

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed flexible packaging roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Flexible Packaging and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

BOPP (Biaxially Oriented Polypropylene)

CPP (Cast Polypropylene)

Kraft Paper

Polyethylene (PE)

Bioplastics

Frequently Asked Questions

About Flexible Packaging

What types of flexible packaging do you offer?

What materials are used in your flexible packaging?

Can you provide custom printing on the packaging?

Do you offer samples before placing a bulk order?

What barrier properties do your flexible packages have?

What quality control measures do you have in place?

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.

WhatsApp: +86-15057184967

Email: [email protected]