What Is Pouch Film Laminations

Pouch Film Laminations Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Pouch Film Laminations achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

The Application Of Pouch Film Laminations

1

1. Food Packaging:

2

2. Pharmaceutical and Healthcare:

3

3. Cosmetic and Personal Care:

4

4. Industrial and Agricultural:

5

Key Benefits of Pouch Film Laminations:

Key Features Of Pouch Film Laminations

Enhanced Barrier Properties: This is perhaps the most critical feature. Lamination allows for the combination of layers that block oxygen, moisture, light, and aromas far more effectively than single films. This is essential for preserving product freshness and extending shelf life.

Increased Mechanical Strength & Durability: By combining layers, the film gains significant resistance to tearing, puncturing, and abrasion. This ensures the pouch remains intact during manufacturing, transit, and handling, protecting the product inside.

Optimized Seal Strength and Integrity: The innermost layer is specifically chosen for its ability to create strong, reliable, leak-proof seals when exposed to heat and pressure during the pouch-making or filling process.

Protected Graphics (Reverse Printing): Printing on the back of a transparent outer layer and then laminating other layers behind it protects the ink from scuffing, scratching, and contact with the product, resulting in durable and high-quality visual branding.

Contact us to discuss your Pouch Film Laminations solutions!

We’d like to bring value and save cost for your Pouch Film Laminations.

Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Pouch Film Laminations?

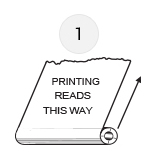

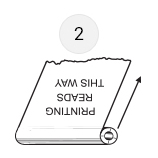

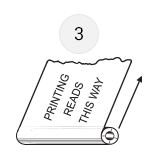

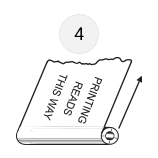

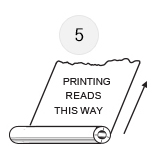

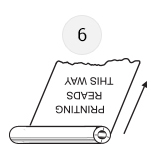

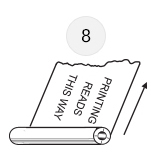

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed Pouch Film Laminations roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Pouch Film Laminations and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

BOPP (Biaxially Oriented Polypropylene)

Polyethylene (PE)

1. Why should I choose a laminated film instead of a single-layer film for my pouches?

2. What are the main benefits of using laminated films for pouches?

3. What is the difference between a 2-layer and a 3-layer laminate?

4. What materials are commonly used as the outer layer in pouch laminations?

5. What is the function of the barrier layer in a laminate?

6. What material is typically used as the sealant layer, and why?

7. What is the role of aluminum foil in pouch laminations?

8. Why is Nylon (PA) sometimes included in a laminate structure?

9. What is reverse printing and why is it used in laminations?

10. How does lamination improve the barrier properties compared to single films?

11. Does the lamination process affect the strength or durability of the film?

12. How does the laminate structure impact the seal strength of the pouch?

13. What are the common lamination processes you use?

14. Can I customize the specific layers and their thicknesses in a laminate for my product?

15. How does the complexity of the laminate structure affect the cost?

16. Are laminated films recyclable? What about compostable options?

17. How are the barrier properties of a finished laminate tested and measured?

18. What is delamination, and why is it a concern?

19. Is laminated film compatible with Vertical Form Fill Seal (VFFS) or Horizontal Form Fill Seal (HFFS) machines?

20. How does the choice of lamination impact the product's overall shelf life on the store shelf?

Frequently Asked Questions

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.