Mono-material packaging has become one of the most talked-about topics in sustainable packaging.

Designed around a single material family, most commonly polyethylene (PE) or polypropylene (PP), mono-material structures are often promoted as a more recyclable alternative to traditional multi-layer flexible packaging.

In the right application, mono-material packaging can be an effective solution.

In the wrong one, it can introduce performance risks that undermine both sustainability goals and product integrity.

For brands pursuing real, defensible sustainability, understanding where mono-material works. And where it does not. Is essential.

Why Mono-Material Packaging Is Gaining Attention

The appeal of mono-material packaging is easy to understand.

From a recycling standpoint, simpler material streams are easier to collect, sort, and reprocess. Many recycling systems are not equipped to handle complex multi-material laminates. Mono-material structures, in contrast, can align more closely with existing infrastructure in certain regions.

For brand owners, mono-material packaging also offers clear advantages:

-

Straightforward sustainability messaging

-

Alignment with recyclability guidelines

-

Easier communication with regulators and consumers

This is why mono-material solutions feature prominently in many sustainability roadmaps.

But recyclability alone does not define packaging performance. Or sustainability.

What “Mono-Material” Really Means in Flexible Packaging

In flexible packaging, mono-material does not mean a single layer.

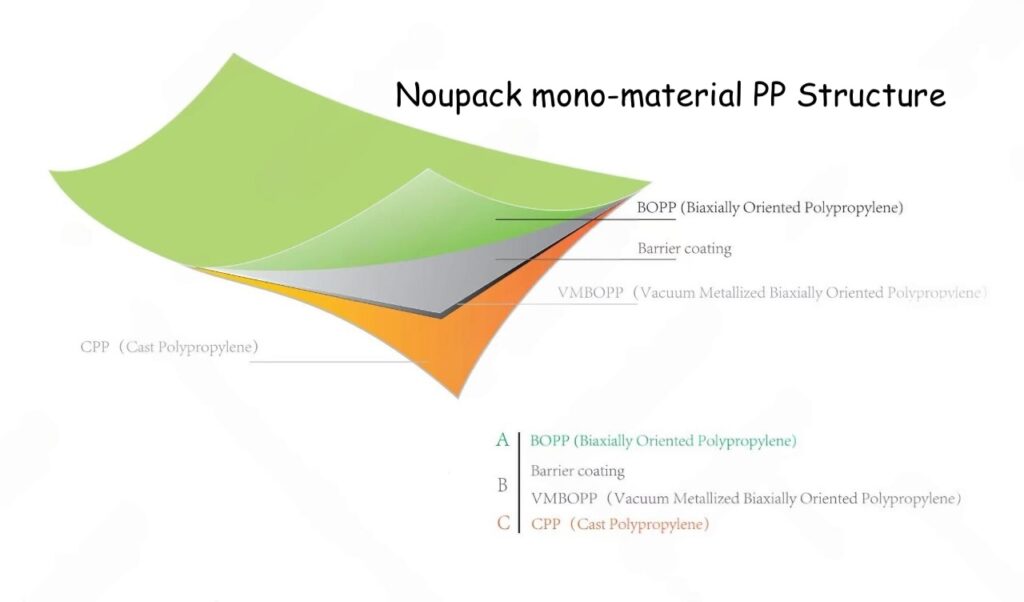

Most mono-material structures still consist of multiple layers. They simply belong to the same polymer family, such as all-PE or all-PP constructions. These structures may include:

-

Multiple functional layers

-

Barrier or protective coatings

-

Modified resin blends

The challenge lies in achieving the same balance of barrier performance, mechanical strength, sealability, and processing stability that traditional multi-material structures deliver. But with a far more limited material toolkit.

This is where trade-offs begin.

Where Mono-Material Packaging Performs Well

Mono-material packaging can be highly effective when product requirements and supply chain conditions are relatively forgiving.

Applications With Lower Barrier Demands

Products that are less sensitive to oxygen, moisture, or light are often good candidates. Examples include:

-

Certain dry goods

-

Short shelf-life products

-

Non-food or secondary packaging

In these cases, the reduced barrier performance of mono-material structures may still be sufficient.

Stable and Controlled Supply Chains

Mono-material solutions perform best in supply chains with:

-

Short transportation distances

-

Predictable storage conditions

-

Limited exposure to temperature and humidity fluctuations

When external stresses are low, simpler structures are less likely to fail.

Brands With Strong Process Control

Brands operating well-controlled filling environments, and with the ability to fine-tune equipment settings, often achieve better results with mono-material packaging.

When product, structure, and machinery are developed together, consistency improves. And risks decrease.

Where Mono-Material Packaging Reaches Its Limits

Despite its benefits, mono-material packaging is not a universal solution.

High-Barrier Product Requirements

Many food, pet food, and medical products depend on strong protection against:

-

Oxygen ingress

-

Moisture transmission

-

Aroma loss or contamination

Replicating this level of protection with mono-material structures often requires compromises. Increased material thickness. Additional coatings. Or both.

These changes can reduce material efficiency and complicate recyclability claims. In some cases, they eliminate the intended sustainability benefit altogether.

Long and Complex Supply Chains

Export-driven supply chains place significant stress on packaging:

-

Long transit times

-

Wide temperature variation

-

Mechanical compression during transport

-

Multiple handling points

A mono-material structure that performs well in local trials may struggle under these conditions. The result can be leakage, spoilage, or costly returns.

From a lifecycle perspective, product loss carries a far greater environmental impact than packaging material complexity.

Operational and Sealing Sensitivity

Mono-material structures often have narrower processing windows. Seal integrity, in particular, can be more sensitive to:

-

Line speed fluctuations

-

Temperature variation

-

Equipment wear

For high-speed or multi-site operations, maintaining consistent performance can be more challenging than with balanced multi-material structures.

The Sustainability Trade-Off Brands Must Face

The real question is not whether mono-material packaging is recyclable.

The real question is whether it delivers net sustainability benefits across the entire system.

If a mono-material solution:

-

Requires significantly more material to achieve basic performance

-

Increases production reject rates

-

Shortens shelf life

-

Leads to higher levels of product waste

Then the sustainability equation becomes far more complex.

In these cases, a well-designed multi-material structure, optimized for material efficiency and performance stability, may result in a lower overall environmental footprint.

Mono-Material vs. Multi-Material Is a False Choice

Positioning mono-material and multi-material packaging as opposing options oversimplifies the decision.

Sustainable packaging development is not about choosing one structure for all products. It is about matching the right structure to the right application.

For some products, mono-material packaging is the best solution.

For others, performance-driven multi-material structures remain essential.

The most effective approach is not ideological. It is analytical.

Questions Brands Should Ask Before Switching

Before committing to a mono-material solution, brands should ask:

-

What level of barrier performance does the product truly require?

-

How long and complex is the supply chain?

-

What are the real operating conditions on the filling line?

-

What is the environmental cost of potential product loss?

-

Can sustainability claims be supported by consistent real-world performance?

These questions shift the discussion from material preference to system performance.

Sustainability Is Measured by Outcomes

Mono-material packaging is an important tool. But it is not a universal answer.

True sustainability is measured by outcomes:

-

Reliable product protection

-

Operational efficiency

-

Waste reduction across the full lifecycle

-

Credible and defensible environmental claims

In flexible packaging, structure remains the deciding factor. It determines whether a mono-material solution delivers value. Or introduces unintended risk.

A Practical Perspective From Noupack

At Noupack, we believe sustainability starts with performance.

We work with brands to evaluate packaging structures based on real product needs, real supply chains, and real operating conditions. Sometimes that leads to mono-material solutions. When they make sense. When they perform. And when they truly reduce environmental impact.

In other cases, a carefully engineered multi-material structure remains the more responsible choice.

Our approach is not about following trends.

It is about designing packaging that protects products, supports operations, and delivers measurable sustainability outcomes.

Because in the end, the most sustainable package is not defined by how simple it looks on paper.

It is defined by how reliably it performs in the real world.