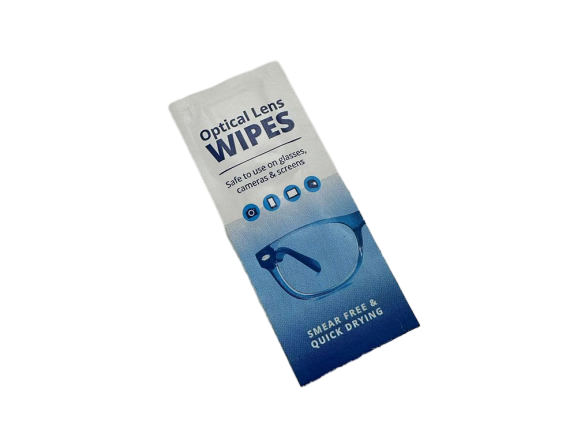

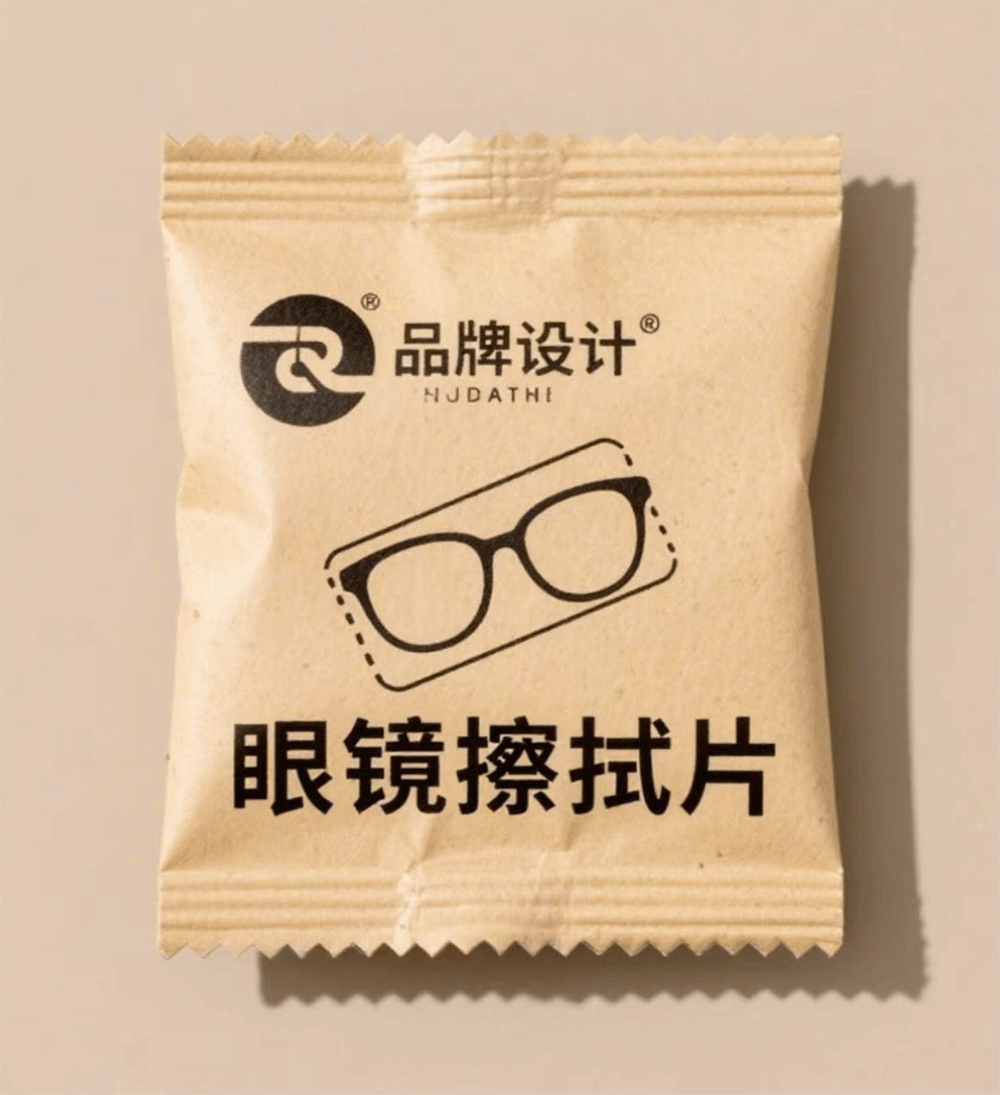

Lens cleaning wipe packaging

A small bag or container designed to hold lens cleaning wipes

Lens Cleaning Wipe Packaging Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Lens Cleaning Wipe Packaging achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

What Is Lens Cleaning Wipe Packaging

lens cleaning wipe pouch refers to a type of packaging made from non-rigid materials that can easily change shape, allowing for a versatile and efficient way to package products.

lens cleaning wipe pouch encompasses any packaging that can be molded, folded, or shaped to fit the product it contains. This includes materials such as plastic films, paper, aluminum foil, and combinations of these materials. Common forms include bags, pouches, wraps, and liners.

Key Features Of Lens Cleaning Wipe Packaging

- Easy to open and close: The packaging is designed to be easily opened by consumers without the need for additional tools. At the same time, it should also be easy to close to ensure the remaining wipes are still protected when not in use. This is commonly seen in packaging with tear – notches or resealable zippers.

- Portability: Lens cleaning wipe packaging is often designed to be compact and lightweight for easy carrying in bags, pockets, or camera cases. This allows users to clean their lenses whenever and wherever needed. Blister packs or small – sized flat bags are typical portable packaging forms.

- Moisture – proof: The packaging material should have good moisture – resistance to prevent the lens cleaning wipes from drying out. This is usually achieved by using materials like aluminum – plastic composite films or polyethylene – coated papers, which can effectively block the invasion of external moisture.

- Dust – proof and anti – contamination: It should be able to prevent dust, dirt, and other contaminants from coming into contact with the wipes. Sealed packaging structures, such as sealed bags or boxes with tight – fitting lids, are often employed to keep the wipes clean and hygienic.

The Application Of Lens Cleaning Wipe Packaging

- Moisture and Contamination Barrier: The packaging acts as a barrier against moisture, air, and dust, preventing the wipes from drying out and becoming contaminated. This is essential as the cleaning effectiveness of the wipes depends on the preservation of their active ingredients. For example, in high – humidity environments, without proper packaging, the wipes could absorb excess moisture, leading to mold growth or a reduction in the efficacy of the cleaning agents.

- Physical Protection: It protects the wipes from physical damage during storage and transportation. The packaging material is usually sturdy enough to withstand impacts and pressure, ensuring that the wipes remain intact and in good condition. This is particularly important for delicate lens – cleaning wipes, as any damage to the wipe could potentially scratch the lens surface.

Contact us to discuss your Alcohol Swab Packaging Bag!

We’d like to bring value and save cost for your Lens Cleaning Wipe Packaging.

Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Lens Cleaning Wipe Packaging?

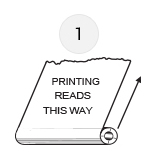

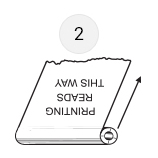

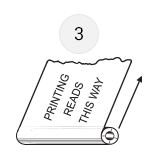

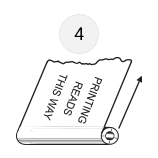

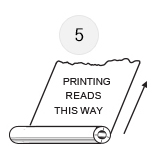

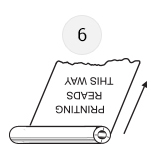

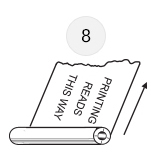

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed flexible packaging roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Lens Cleaning Wipe Packaging and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

BOPP (Biaxially Oriented Polypropylene)

CPP (Cast Polypropylene)

Kraft Paper

Polyethylene (PE)

Bioplastics

Frequently Asked Questions About Lens Cleaning Wipe Packaging

You are welcome to contact us for any questions unclear or interested, we are open to exchange ideas about this Lens Cleaning Wipe Packaging makret with you.

1. How effective is this packaging in maintaining the moisture of the wipes?

Answer: Our packaging uses high-barrier materials that can effectively block the entry of air and moisture, maximizing the retention of the wipes’ moisture. Through rigorous testing, under normal temperature and humidity conditions, the wipes can be ensured to maintain a good moist state throughout the shelf life, meeting your cleaning needs.

2. Is the packaging material safe? Does it meet relevant standards?

Answer: The packaging material is completely safe and meets food-grade and medical-grade relevant standards. Whether it comes into direct contact with the lens or is used in daily life, it will not cause any harm to the human body. At the same time, it will not corrode or damage the lens, so you can use it with confidence.

3. Can the size and shape of the packaging be customized?

Answer: Certainly. We can customize various sizes and shapes of packaging according to your wipe size and special design requirements. Whether it is a regular rectangle or a unique special shape, we can meet your needs and help you create a recognizable product.

4. How is the sealing performance of the packaging ensured?

Answer: We use advanced heat-sealing technology and high-quality sealing materials to ensure that every seal of the packaging is tight. During the production process, strict sealing tests will be carried out on each package to eliminate leakage problems and keep the wipes clean and sterile at all times.

5. Can our brand logo and product information be printed on the packaging?

Answer: No problem. We have a professional printing team and advanced printing equipment that can clearly and accurately print your brand logo, product description, usage instructions, and other information on the packaging, enhancing the brand image and promoting product sales.

6. Is the packaging easy to open and close?

Answer: We have designed a user-friendly opening and closing method. For example, the easy-tear opening design is convenient for the first opening, and the self-sealing strip or zipper closure is convenient for multiple openings and closings, making it easy and convenient for consumers to use while maintaining the packaging’s sealing performance.

7. Is the packaging easy to damage during transportation?

Answer: We have rich experience in packaging transportation. We will use sturdy outer packaging materials and add cushioning materials inside to ensure that the packaging can withstand a certain degree of and extrusion during transportation, minimizing the risk of damage. If there is any transportation damage, we also have a complete after-sales guarantee measure.

8. How is the cost of the packaging calculated?

Answer: The packaging cost mainly depends on factors such as material selection, size, printing process, and order quantity. The more advanced the material, the larger the size, and the more complex the printing, the relatively higher the cost; the larger the order quantity, the lower the unit cost. We will provide you with a detailed and accurate cost quotation according to your specific needs.

9. If I am not satisfied with the packaging design, is there a modification service?

Answer: We attach great importance to customer satisfaction. During the design stage, we will maintain close communication with you and make modifications according to your feedback until you are satisfied with the design. If you have new ideas or modification suggestions before production, we will also actively cooperate with the adjustment.

10. What types of lens cleaning wipes is this packaging suitable for?

Answer: Whether it is ordinary glasses lens cleaning wipes, camera lens cleaning wipes, or electronic screen cleaning wipes, our packaging is suitable. It can effectively protect the cleaning ingredients of the wipes and ensure the best cleaning effect when in use.

11. How transparent is the packaging? Can it display the condition of the wipes?

Answer: We offer a variety of packaging material options, some of which have high transparency, allowing consumers to clearly see the quantity and condition of the wipes, increasing the product’s attractiveness and credibility. At the same time, it is also convenient for consumers to intuitively understand the product.

12. Are there any environmentally friendly packaging materials available?

Answer: Yes. We keep up with the environmental protection trend and provide a variety of environmentally friendly packaging materials, such as biodegradable plastics, paper packaging, etc. These materials can reduce the impact on the environment while meeting the packaging function, in line with the current environmental protection concept and relevant policy requirements.

13. How is the moisture-proof performance of the packaging?

Answer: The packaging has excellent moisture-proof performance. The moisture-proof materials used can effectively resist external moisture, prevent the wipes from getting moldy and deteriorating due to moisture, and ensure that the wipes maintain good quality in various humidity environments.

14. If I need a small batch order, do you accept it?

Answer: We accept small batch orders. Although large-scale orders can enjoy more favorable prices, we also understand the needs of customers for small batch packaging in the new product testing or market promotion stage and will do our best to meet your different order size requirements.

15. How is the heat resistance of the packaging?

Answer: The packaging materials are carefully selected and have good heat resistance. In common high-temperature environments, such as the temperature in the car in summer, the packaging will not deform, melt, or affect the quality and cleaning effect of the wipes, ensuring the stability of the product in different environments.

16. What are the product quality inspection standards?

Answer: We have a strict quality inspection system. Every link from raw material procurement, production process to finished product packaging is inspected according to international and domestic relevant standards. This includes sealing detection, material strength testing, printing clarity inspection, etc., to ensure that every package delivered to you meets high-quality standards.

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.