Flexographic Printing

Noupack has sufficient capacity to meet the demands of flexographic printing production.

About Noupack Flexographic Printing

Noupack flexographic printing is a form of relief printing that employs flexible plates made from rubber or photopolymer. This method is particularly well-suited for high-volume jobs and is known for its ability to produce sharp images and vibrant colors quickly and cost-effectively.

Substrates: Noupack flexo can print on a wide range of materials, including paper, plastic films, metallic films, cardboard, and non-woven fabrics. This versatility makes it ideal for packaging applications, labels, newspapers, and other printed materials.

Advantages of Noupack Flexographic Printing

Speed and Efficiency: Flexo can achieve high speeds (up to 2000 linear feet per minute), making it suitable for large volume runs.

Cost-Effectiveness: With lower setup times and reduced waste compared to traditional methods like offset printing, flexo is ideal for long-term repeat orders.

High Quality: Advances in plate technology and ink formulations have improved the quality of flexo prints significantly, allowing for vibrant colors and intricate designs.

Versatility: The ability to print on various substrates and use different inks makes flexography adaptable for many applications in packaging and labeling.

How Noupack Flexographic Printing Works

Plate Creation: The process begins with the creation of a relief image on flexible plates. These plates are either made from rubber or photopolymer materials and are mounted onto cylinders.

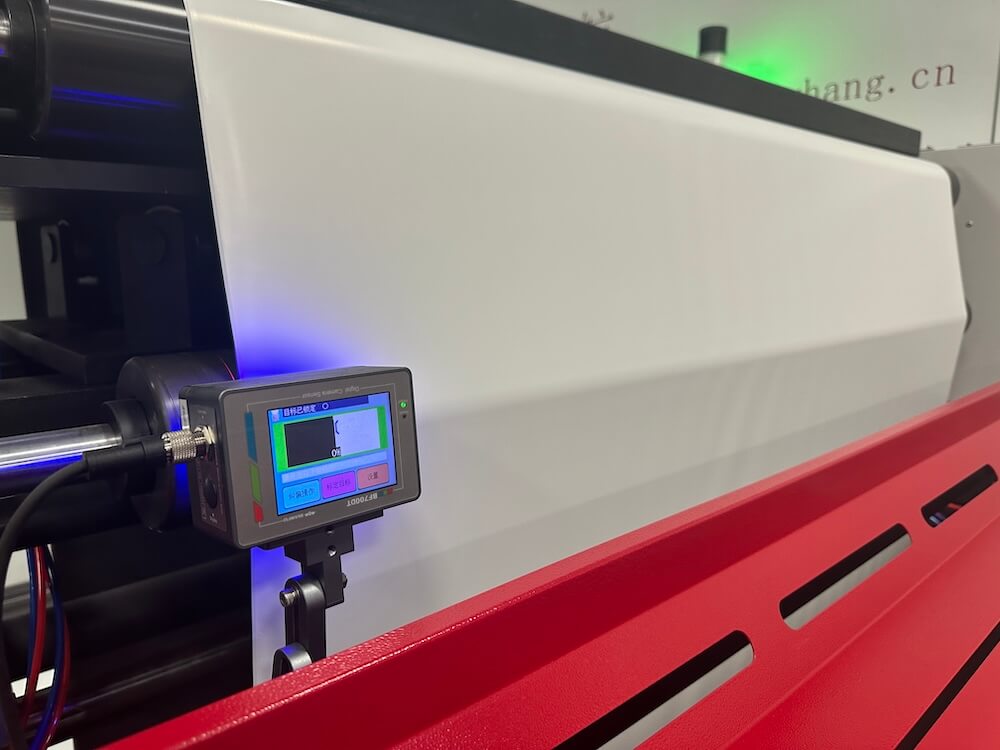

Ink Application: An anilox roller, which has engraved cells to hold ink, transfers a uniform layer of ink from an ink fountain to the plate. The doctor blade may be used to remove excess ink from the anilox roller.

Printing Process: As the substrate (material to be printed on) passes between the plate cylinder and an impression cylinder, pressure is applied to transfer the ink from the raised areas of the plate onto the substrate.

Drying: The ink dries quickly due to its low viscosity, often using ultraviolet (UV) lamps or infrared (IR) dryers, allowing for fast production speeds and preventing smearing between print stations.

Finishing Options: Flexographic presses can integrate additional processes such as laminating, embossing, cold foil stamping, and die-cutting in a single pass, enhancing efficiency and reducing production time.

Contact Us to Custom Your Flexible Packaging

We’re ready to help you improve your packaging solutions here.

Common Materials Used in Noupack Composite Packaging and Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

BOPP (Biaxially Oriented Polypropylene)

CPP (Cast Polypropylene)

Kraft Paper

Polyethylene (PE)

Bioplastics

Production Process Videos

Stay tuned for our upcoming video series, where we delve deeper into our products and processes, showcasing how Noupack can elevate your brand.

Frequently Asked Questions

About Flexographic Printing

What types of substrates can you print on using flexographic printing?

How many colors can you print in a single run with your flexographic printing process?

What quality control measures do you have in place during the flexographic printing process?

How is pricing determined for flexographic printing services?

Do you offer eco-friendly ink options for your flexographic printing services?

Can you provide samples of previous flexographic printing jobs before placing an order?

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.