Flexible Packaging Film Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Flexible packaging film achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

Our Product

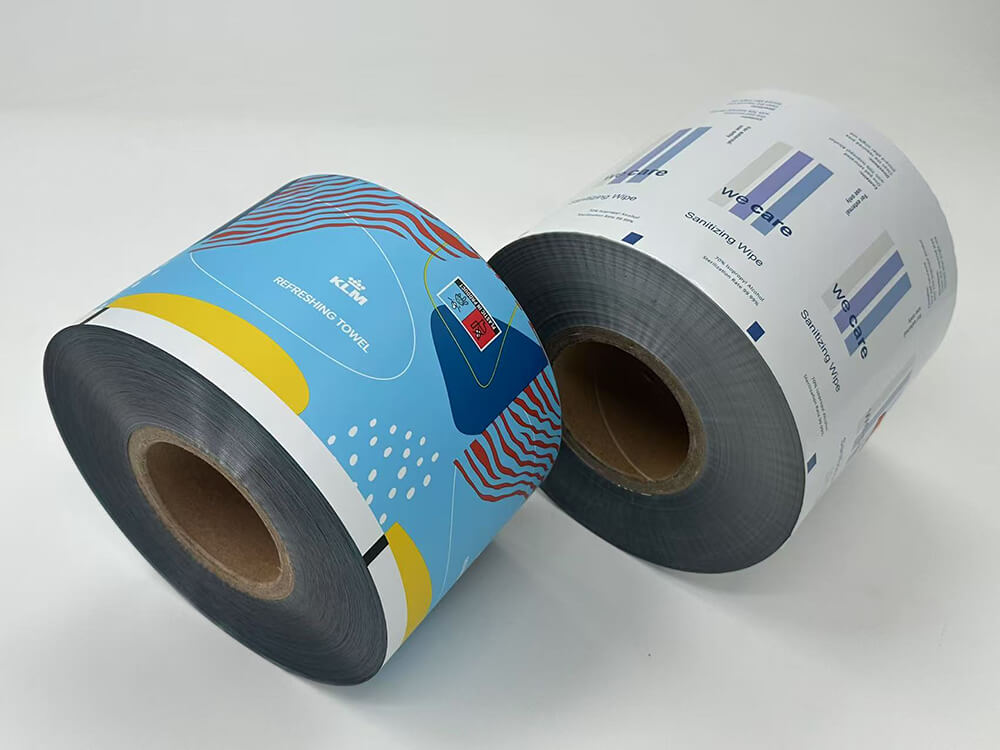

Our product: Plastic film rolls, Flexible Packaging Materials, Laminating Paper, Aluminum Foil Laminating Paper, Pouches and Bags for snacks, coffee, wine, sugar sachet, Alcohol swab packaging bag etc.

Pet food bag

coffee bag

Resealable Bag

Slider Pouches

Glass cleaning wipes

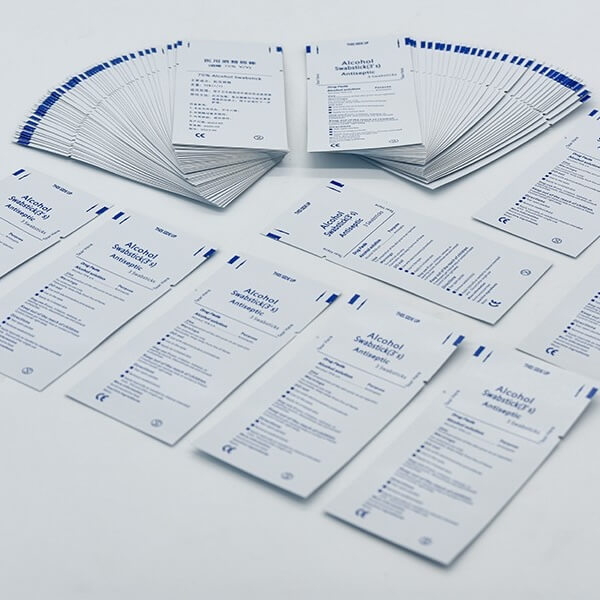

Alcohol Swab Packaging Bag

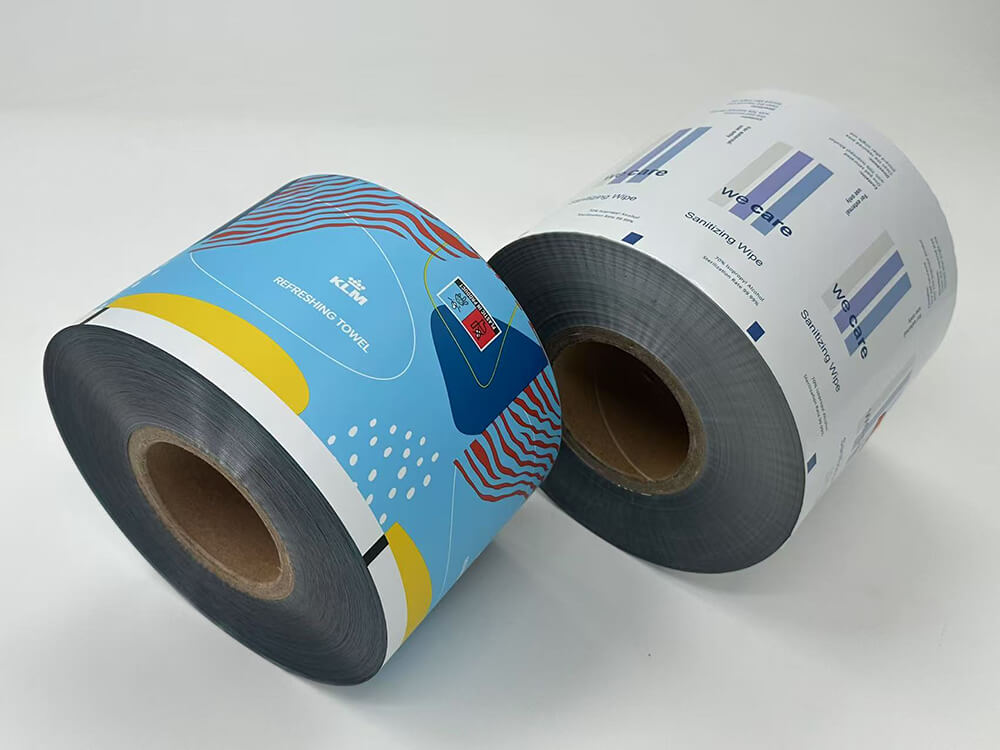

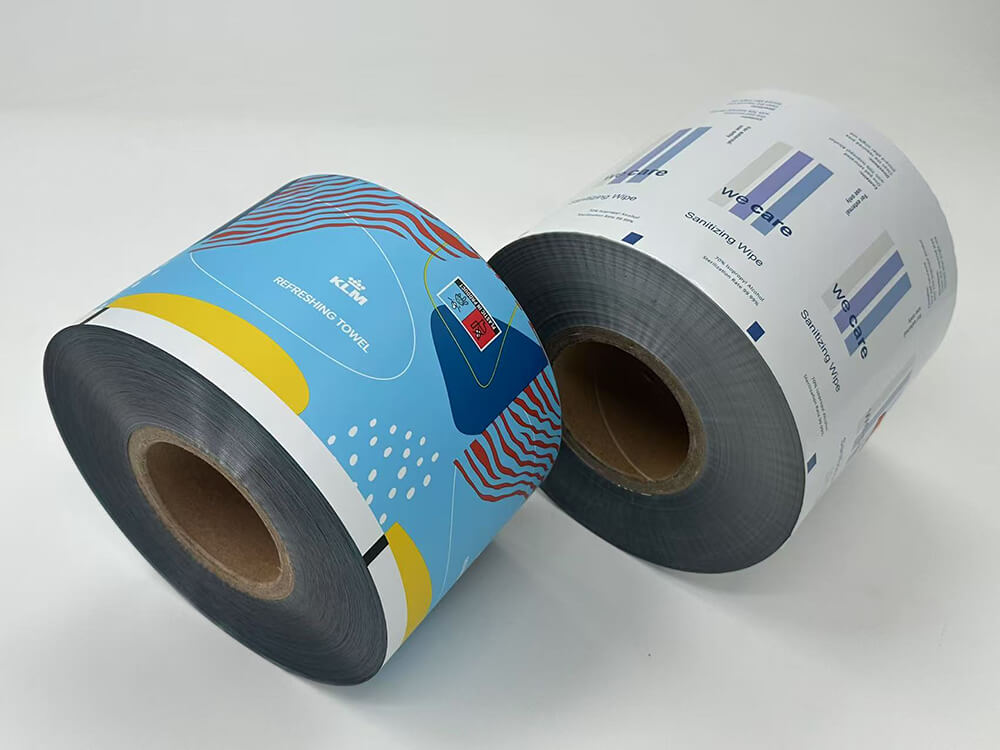

Pouch Film Laminations

Alcohol Swab Packaging Bag

Flexible Packaging Film

Flexible Packaging Film

Flexible Packaging Film

Flexible Packaging Film

The Aplication of Flexible Packaging Film

1. Food and Beverage Industry:

2. Pharmaceutical and Healthcare Industry:

3. Cosmetic and Personal Care Industry:

4. Industrial and Agricultural Applications:

Key Advantages Driving These Applications:

Barrier Properties: Protection against moisture, oxygen, light, and aromas, extending shelf life and maintaining product quality.

Flexibility in Design: Ability to create various shapes, sizes, and convenient features like zippers, spouts, and easy-tear notches.

Cost-Effectiveness: Often more economical than rigid packaging in terms of material usage, transportation, and storage.

Lightweight: Reduces shipping costs and is more convenient for consumers.

Sustainability: Can be designed with reduced material usage and increasing recyclability options.

What Is Flexible Packaging Film

Flexible packaging refers to a type of packaging made from non-rigid materials that can easily change shape, allowing for a versatile and efficient way to package products.

Flexible packaging encompasses any packaging that can be molded, folded, or shaped to fit the product it contains. This includes materials such as plastic films, paper, aluminum foil, and combinations of these materials. Common forms include bags, pouches, wraps, and liners.

Key Features Of Flexible Packaging Film

Flexibility and Adaptability: As the name suggests, it can easily conform to the shape of the product being packaged, offering versatility in package design and efficient use of space.

Lightweight: Compared to rigid packaging alternatives like glass, metal, or rigid plastics, flexible film is significantly lighter. This reduces transportation costs and the overall environmental footprint related to shipping.

Barrier Properties: Flexible films can be engineered (often through lamination or special coatings) to provide excellent barriers against external elements like moisture, oxygen, light, and aromas, crucial for preserving product freshness and extending shelf life.

Durability and Strength: Despite being thin, flexible films can be surprisingly strong and resistant to tearing and puncturing, protecting the product from damage during handling and distribution.

Cost-Effectiveness: Flexible packaging often requires less material than rigid options, leading to lower material and production costs. Its lightweight nature also contributes to lower transportation expenses.

The Details Of Flexible Packaging Film

Flexible packaging film refers to non-rigid packaging made from materials like plastic, paper, aluminum foil, or combinations of these. It’s designed to be easily formed into various shapes and sizes to contain and protect products.

Common Materials:

- Polyethylene (PE): Offers good heat-sealing properties and is cost-effective. Different densities (LDPE, LLDPE, HDPE) provide varying levels of flexibility and strength.

- Polypropylene (PP): Known for its clarity, stiffness, and good moisture barrier. BOPP (Biaxially Oriented PP) is often used for printing. CPP (Cast PP) has good heat sealability.

- Polyester (PET): Provides high tensile strength, stiffness, and good temperature resistance. It’s often used when durability is needed.

- Nylon (Polyamide – PA): Offers excellent puncture resistance and good oxygen barrier properties.

- Aluminum Foil (Al): Provides an excellent barrier against moisture, oxygen, and light.

- Metallized Films (VMPET, VMBOPP): Offer a metallic appearance and improved barrier properties compared to non-metallized films.

- Ethylene Vinyl Alcohol (EVOH): An excellent oxygen barrier material, often used as a thin layer in laminations.

- Paper: Can be used alone or in laminations, offering printability and a more sustainable image.

Common Applications:

- Food Packaging: Snacks, confectionery, frozen foods, liquids, powders, fresh produce, pet food.

- Pharmaceuticals: Sachets, blister packs.

- Cosmetics and Personal Care: Sample pouches, single-use packs, refill pouches.

- Industrial Goods: Protective coverings, bags for components.

- Agricultural: Greenhouse coverings, mulching films.

- E-commerce: Protective packaging for shipping.

Manufacturing Process (General Steps):

- Extrusion: Polymers are melted and forced through a die to create a thin film. This can be a blown film or cast film process.

- Printing: The film is often printed with brand information, product details, and graphics using methods like flexography, rotogravure, or digital printing.

- Lamination (if needed): Multiple layers of different films are bonded together using adhesives or heat to achieve specific properties.

- Slitting: Large rolls of film are cut into narrower rolls of the desired width.

- Bag/Pouch Making: The film rolls are then fed into bag-making machinery that forms, fills (sometimes), and seals the final package.

Contact us to discuss your Flexible Packaging Film solutions!

We’d like to bring value and save cost for your flexible packaging.Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Film Packaging?

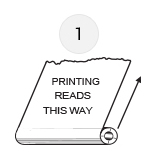

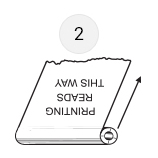

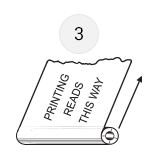

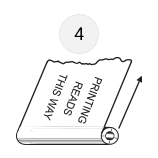

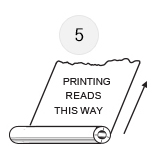

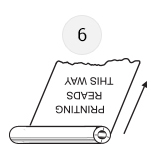

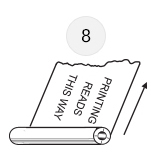

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed flexible packaging roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Flexible Packaging Film and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

CPP (Cast Polypropylene)

Polyethylene (PE)

1. What is flexible packaging film?

2. What materials are commonly used for flexible packaging films?

3. What is a film structure or laminate?

4. How do I choose the right film structure for my product?

5. What kind of barrier properties can you provide?

6. What about moisture barrier properties?

7. Can this film help extend my product's shelf life?

8. How strong and durable is the film?

9. Is the film suitable for my specific sealing method?

10. What printing options do you offer?

11. What kind of artwork files do you need for printing?

12. Can you customize the size and shape of the pouches or film?

13. Can you add features like zippers, tear notches, or hang holes?

14. What is the minimum order quantity (MOQ)?

15. How is the pricing determined for flexible packaging film?

16. What is your typical lead time for an order?

17. Do you offer sustainable or eco-friendly flexible packaging options?

18. Is your flexible packaging film food-grade and safe for direct food contact?

19. How do you ensure the quality and consistency of your film?

20. How can I be sure this film will run well on my existing packaging machine?

Frequently Asked Questions

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.