In today’s fast-evolving packaging landscape, flexible packaging has emerged as one of the most popular and versatile solutions. From snacks and beverages to pharmaceuticals and personal care products, flexible packaging is everywhere. Its popularity stems from its ability to deliver convenience, protect products, and align with sustainability goals. But behind every successful flexible package is a carefully crafted “formula” that combines materials, design, and production methods to meet specific needs.

In this blog, we’ll dive into the core elements of flexible packaging, exploring how different materials, technologies, and design strategies come together to create packaging that performs well on shelves and in consumers’ hands.

The Essential Elements of Flexible Packaging

The flexible packaging formula isn’t a one-size-fits-all recipe. It’s a dynamic mix of materials, design choices, and production methods, each chosen for their unique benefits. Here’s a breakdown of the key components:

- Material Selection: The heart of flexible packaging lies in the choice of materials. Flexible packaging is typically made from various films, foils, and papers that are layered together for maximum effectiveness. Here are some of the most common materials used in the formula:

- Polyethylene (PE): This is one of the most widely used materials in flexible packaging. PE offers great flexibility and durability and can be used in a variety of forms such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE). It is commonly used in bags, wraps, and liners.

- Polypropylene (PP): Known for its clarity, strength, and resistance to grease, polypropylene is commonly used in packaging for snacks, frozen foods, and consumer goods that need moisture and air protection.

- Polyester (PET): PET is known for its ability to maintain its shape and resist high temperatures. It’s used in products like beverages and medical packaging, where structural integrity and protection are crucial.

- Aluminum Foil: Often used as a barrier layer, aluminum foil is highly effective at keeping out moisture, air, and light. It’s a go-to material for products like chips and coffee, where maintaining freshness and flavor is key.

- Paper-Based Materials: Although not as common as plastic, paper-based flexible packaging is gaining popularity for its renewable, eco-friendly nature. It’s used in combination with plastic liners to provide protection while minimizing environmental impact.

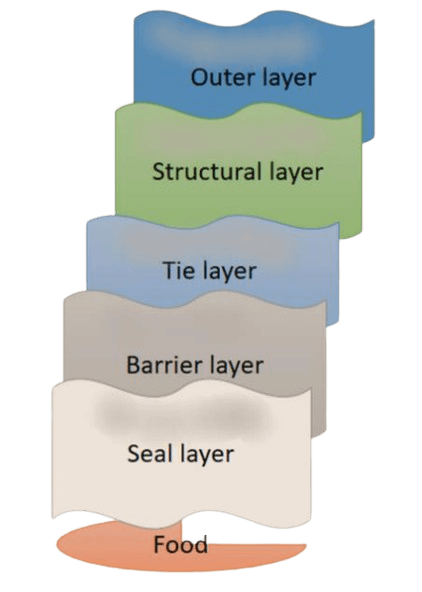

- Barrier Properties: One of the key advantages of flexible packaging is its ability to protect products from external factors like oxygen, moisture, light, and contaminants. Creating packaging that offers the right kind of protection for a given product is vital. Here’s a closer look at some of the barrier properties flexible packaging can offer:

- Oxygen and Moisture Barriers: For perishable products like chips and snacks, packaging must keep out moisture and oxygen to prevent spoilage. Multi-layered packaging that includes materials like PE and aluminum foil helps achieve this.

- Light Protection: Some products, such as coffee, oils, and snacks, degrade when exposed to light. Flexible packaging with opaque layers or foil is used to shield products from light, preserving their freshness and quality.

- Chemical Barriers: Certain items, such as cleaning products or chemicals, require packaging that can resist harsh substances. Flexible packaging can be tailored with layers that provide this protection, ensuring the packaging maintains its integrity.

- Sustainability Considerations: In recent years, sustainability has become an increasingly important focus for the packaging industry. As consumers demand eco-friendly options, flexible packaging companies are embracing greener alternatives. Here’s how sustainability is impacting the flexible packaging formula:

- Recyclable Materials: Companies are shifting toward recyclable flexible packaging options, such as mono-materials that make recycling easier. Mono-material packaging uses a single type of plastic, reducing the complexity of recycling compared to multi-layered materials.

- Biodegradable Plastics: Another growing trend is the use of biodegradable plastics. These materials break down naturally over time, reducing waste and environmental impact. Though still not as widely used as recyclable plastics, biodegradable options are gaining traction in industries such as food and beverage.

- Reduced Waste: Flexible packaging often uses fewer materials and is lighter than traditional packaging options, leading to reduced waste and lower carbon footprints. The compact nature of flexible packaging also reduces transportation costs, further minimizing environmental impact.

- Printing and Branding: Flexible packaging isn’t just about protection and sustainability—it’s also about standing out on the shelf. Printing technologies play a big role in creating visually appealing packaging that attracts consumers. Some common printing methods include:

- Flexographic Printing: Flexography, or flexo printing, is the most common method for printing on flexible packaging. It uses flexible rubber plates to transfer ink onto a substrate, allowing for vibrant, high-quality prints at large scale.

- Digital Printing: As digital technology continues to advance, digital printing is becoming more popular, especially for small production runs and customized designs. It allows brands to create smaller batches of products with unique, personalized designs.

- Embossing and Special Effects: Flexible packaging can also include creative features like embossing, spot UV finishes, and holographic effects. These techniques enhance visual appeal, giving the product a premium look and making it stand out in a crowded marketplace.

- Design Functionality: Beyond protection and aesthetics, flexible packaging also needs to be practical. The design must meet the needs of both the product and the consumer. Here are some functional design elements that make flexible packaging so appealing:

- Resealable Zippers: Packaging that can be resealed after opening is crucial for products like snacks, where freshness must be preserved. Zippers and other closures offer convenience and product longevity.

- Pouches and Bags: Flexible packaging comes in a wide range of formats, including stand-up pouches, gusset bags, and pillow pouches. Stand-up pouches, for example, offer great shelf stability and are ideal for products like chips and granola.

- Portion Control: Flexible packaging can be designed for portion control, offering single-serve pouches or multi-packs that cater to consumers looking for convenience and on-the-go options.

Looking Ahead: The Future of Flexible Packaging

As consumer preferences continue to evolve, so does the flexible packaging formula. The future of flexible packaging will focus on integrating more sustainable practices, utilizing smarter materials and technologies, and meeting the growing demand for personalized products. Innovations such as smart packaging and advanced barrier technologies will likely play an important role in shaping the future of packaging.

Conclusion

Flexible packaging is a multifaceted solution that combines the right mix of materials, protection, sustainability, and functionality. The formula behind flexible packaging is about understanding how each element—from material choice to printing techniques—works together to create an optimal solution for a given product.

In summary, businesses that master the flexible packaging formula will not only meet the growing demands of consumers for convenience, freshness, and sustainability but also position themselves for success in an increasingly competitive market. By embracing innovative materials, adopting eco-friendly practices, and delivering eye-catching designs, flexible packaging companies can continue to thrive as the industry evolves.