Window Clarity Engineering: Balancing Product Visibility and Protection in Packaging Design

In a competitive retail environment, a product’s packaging is its first and most crucial point of communication with the consumer. For many products, especially in the food, cosmetic, and consumer goods sectors, showing the product is a powerful marketing tool. This is where window clarity engineering comes in—the art and science of integrating a transparent […]

Comparative Analysis of Oxygen Barrier Technologies: Mylar Bags vs. Modified Atmosphere Packaging

In the world of long-term food preservation, controlling the environment is everything. Oxygen is a primary enemy of food, leading to spoilage, rancidity, and a loss of nutrients. Two of the most effective technologies for combating this are Mylar bags and Modified Atmosphere Packaging (MAP). While both serve to protect food, they operate on different […]

Luxury Spice Pouch Engineering: Balancing Aesthetics with Functional Requirements

The global spice market is evolving, with a growing segment dedicated to high-end, artisanal products. For these brands, packaging is more than a mere container; it is an integral part of the product experience. Luxury spice pouch engineering is about creating a package that perfectly balances premium aesthetics with functional requirements. It must look and […]

Evaluating Seal Strength in Liquid Packaging: Standards and Testing Procedures

The integrity of a seal is the single most critical factor in liquid packaging. A compromised seal can lead to product spoilage, leakage, and significant financial loss, not to mention a damaged brand reputation. While there are various packaging formats, the spout pouch has become a popular choice for everything from beverages to sauces, offering […]

Sustainable Innovations in Liquid Pouches: Biodegradable Materials and Recyclability Analysis

The liquid packaging industry is undergoing a significant shift, driven by a growing awareness of environmental impact. As consumers and corporations alike seek to reduce plastic waste, the focus is turning to sustainable innovations in liquid pouches. This new generation of packaging is not only designed for convenience and product protection but also for its […]

Biodegradable Sealed Bag Solutions: Material Science Breakthroughs and Market Applications

The evolution of packaging is at a critical juncture, with a strong industry-wide shift toward sustainable solutions. Among these innovations, biodegradable ziplock solutions are gaining significant traction, offering a compelling alternative to conventional plastic for products requiring reusability and secure closure. This new generation of packaging is not merely an eco-friendly substitute; it represents a […]

Compostable Snack Packaging: The New Generation of Eco-Friendly Solutions

The snack food industry is undergoing a significant transformation, driven by both consumer demand and environmental imperatives. As we move away from conventional plastic films, compostable snack packaging is emerging as a leading solution, offering a path to reduce waste without compromising product quality. This new generation of packaging is not just a sustainable alternative; […]

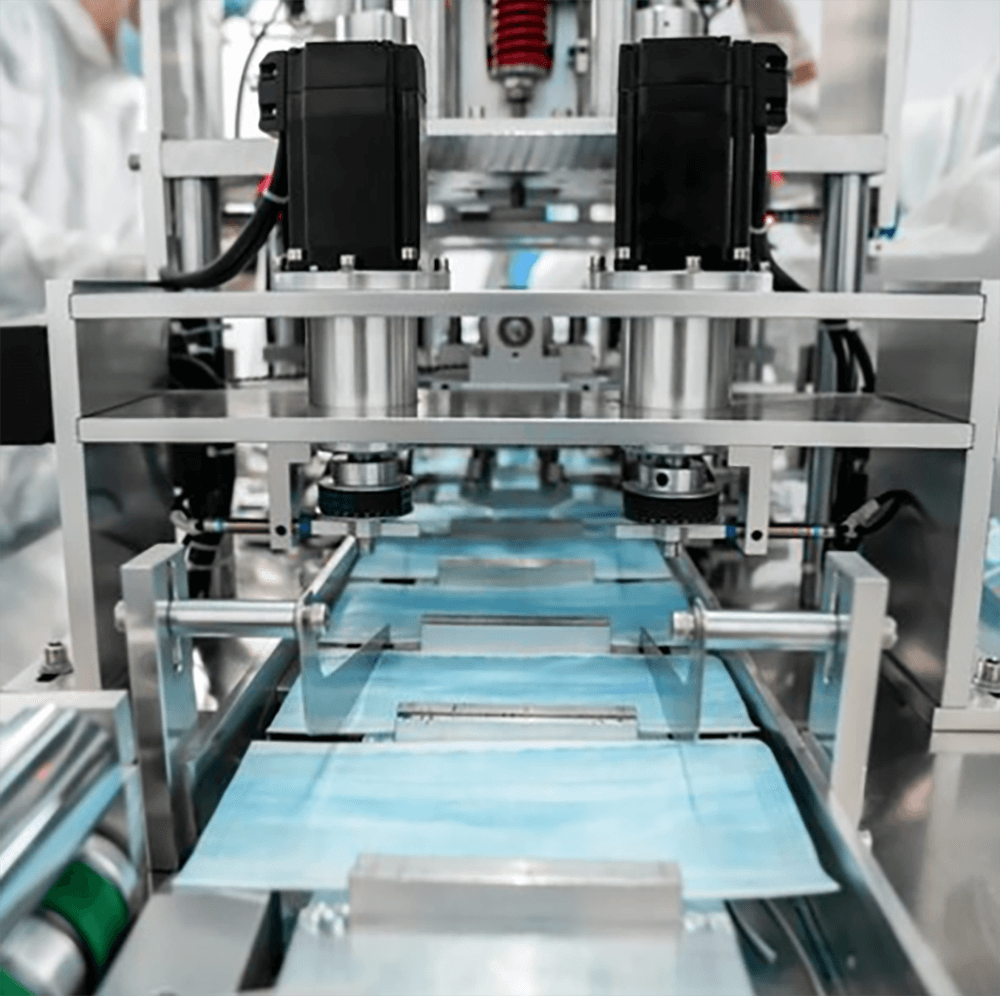

Automated Packaging Technology for Wet Wipes

Wet wipes have become an everyday essential, and the technology behind their production and packaging is undergoing a profound transformation. From simple manual processes to highly automated production lines, technological advancements have not only boosted efficiency but have also significantly improved product quality and safety. This article will delve into several key areas of automated […]

Sustainable Materials Revolution in Stand Up Pouch Manufacturing: Bio-based and Compostable Alternatives

In the dynamic world of packaging, the stand up pouch has emerged as a powerhouse, combining convenience, functionality, and visual appeal. But as environmental concerns take center stage, the industry is undergoing a radical transformation. The focus is shifting from traditional, petroleum-based plastics to sustainable alternatives, with bio-based and compostable materials leading the charge. Bio-based […]