The demand for alcohol wipes has surged in recent years, driven by heightened hygiene awareness and the need for convenient disinfection solutions. Whether used in healthcare, personal care, or household cleaning, alcohol wipes rely on effective packaging to maintain product integrity, extend shelf life, and ensure user convenience. However, designing the perfect alcohol wipes packaging is not as straightforward as it seems. Brands must navigate material compatibility, regulatory compliance, sustainability concerns, and consumer preferences.

This article dives deep into the latest trends, challenges, and innovative solutions shaping the alcohol wipes packaging industry today.

1. The Role of Packaging in Alcohol Wipes’ Performance

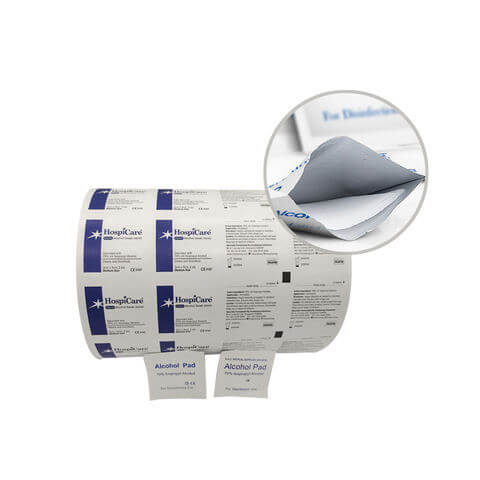

Alcohol wipes contain volatile ingredients, primarily isopropyl or ethyl alcohol, which can easily evaporate if the packaging fails to provide a proper barrier. Packaging must be airtight, durable, and easy to use, ensuring that the wipes remain moist until the last sheet. A poorly designed package can lead to product degradation, loss of effectiveness, and customer dissatisfaction.

Key Packaging Requirements:

- Moisture and Vapor Barrier: High-barrier materials like aluminum foil laminates and multi-layer films help prevent alcohol evaporation.

- Resealability: Flip-top lids, resealable stickers, or zippers are crucial for maintaining product freshness.

- User Convenience: Single-use sachets, travel-friendly packs, and bulk dispensers cater to different consumer needs.

2. Challenges in Alcohol Wipes Packaging

Material Selection and Compatibility

Not all packaging materials are compatible with alcohol-based formulations. Alcohol can degrade certain plastics, leading to leaks or reduced barrier performance. Manufacturers must choose materials with proven chemical resistance, such as PET/PE laminates or aluminum-based films.

Regulatory Compliance

Different regions impose strict regulations on packaging for hygiene products. In the U.S., the FDA governs medical-grade alcohol wipes, while the EPA regulates disinfectant wipes. The EU enforces REACH and CE certifications. Brands must ensure compliance with labeling, safety, and material standards to avoid recalls or legal issues.

Sustainability Pressures

Consumers are demanding eco-friendly packaging, but alcohol wipes present a challenge due to their moisture-sensitive nature. Traditional plastic packaging is hard to replace without compromising product integrity. Brands are now exploring recyclable mono-materials, biodegradable films, and refillable dispensers to reduce their environmental footprint.

3. Innovative Packaging Solutions for Alcohol Wipes

High-Barrier Flexible Packaging

Multi-layer laminates with aluminum or EVOH barriers effectively lock in moisture while offering lightweight, cost-effective solutions compared to rigid containers. Advances in film technology are improving recyclability without sacrificing barrier performance.

Smart Packaging Features

Some brands are integrating QR codes on packaging to provide usage instructions, product authenticity verification, or refill reminders. This enhances consumer engagement while ensuring regulatory transparency.

Sustainable Alternatives

- Mono-Material Pouches: Designed for recycling while maintaining necessary barrier properties.

- Compostable Films: Made from biopolymers, though they currently have limitations in alcohol resistance.

- Refillable Dispensers: Encouraging bulk purchases and reducing single-use packaging waste.

Tamper-Evident and Child-Resistant Features

Given the high alcohol content, packaging must prevent accidental exposure, especially for households with children. Innovations like child-resistant closures and tamper-evident seals improve safety and consumer trust.

4. How to Choose the Right Packaging Partner

Selecting the right packaging supplier is crucial for alcohol wipes manufacturers. Factors to consider include:

- Material Expertise: Ensure the supplier understands barrier requirements for alcohol-based formulations.

- Regulatory Compliance Support: The supplier should help navigate FDA, EPA, and EU requirements.

- Sustainability Commitment: Look for suppliers investing in eco-friendly solutions.

- Customization Capabilities: Ability to provide innovative formats tailored to your brand’s needs.

To stay competitive in the alcohol wipes market, brands must invest in high-barrier, user-friendly, and sustainable packaging solutions. A well-designed package not only preserves product quality but also enhances consumer trust and brand loyalty, and a super supportive supplier like Noupack would make your business not only easier but grow rapidly.

Conclusion

Alcohol wipes packaging is evolving rapidly to meet consumer demands for convenience, safety, and sustainability. Companies that innovate in packaging design—balancing functionality, regulatory compliance, and environmental responsibility—will gain a competitive edge. By leveraging advanced materials, smart packaging features, and eco-friendly solutions, brands can future-proof their products while aligning with industry trends.