Wet wipes have become an everyday essential, and the technology behind their production and packaging is undergoing a profound transformation. From simple manual processes to highly automated production lines, technological advancements have not only boosted efficiency but have also significantly improved product quality and safety. This article will delve into several key areas of automated wet wipes packaging technology, from material selection to the intelligent management of production lines, demonstrating how modern packaging technology is shaping the industry.

Comparing Traditional vs. Eco-Friendly Materials for Wet Wipes Packaging: Performance and Cost Analysis

In the realm of wet wipes packaging, the choice of materials is critical. Traditional packaging materials, such as polyethylene (PE) and polypropylene (PP), have long been popular for their excellent barrier properties and lower cost. They effectively prevent moisture and sanitizing agents from evaporating while protecting against external contamination. However, the non-biodegradable nature of these materials has fueled growing environmental concerns.

In contrast, eco-friendly materials are becoming the new industry favorite. Biodegradable plastics (like PLA) and recyclable composite materials offer a viable solution to environmental problems. While the initial cost of these materials is often higher than traditional plastics, the cost gap is narrowing with technological maturity and scaled production. In terms of performance, the latest generation of eco-friendly materials is meeting or even exceeding the moisture and oxygen barrier properties of traditional materials, providing brands with an option to satisfy consumer demand for sustainability without sacrificing product quality.

Optimizing Production Line Layouts for Maximum Efficiency in Wet Wipes Manufacturing

The layout of a production line is a core factor influencing the efficiency of wet wipes manufacturing. An efficient layout maximizes equipment utilization, minimizes material handling, and reduces operational time.

Lean manufacturing principles are widely applied in the design of wet wipes production lines. By eliminating unnecessary steps, reducing wait times, and ensuring seamless connections between equipment, production speed can be significantly increased. For example, tightly integrating the folding, wetting, and packaging stages and adopting a U-shaped or S-shaped layout can shorten transport distances and reduce production cycles. Furthermore, a modular production line design allows for quick and flexible changes between different product sizes and specifications, thereby improving the overall adaptability of the line.

Implementing AI-Driven Visual Inspection Systems in Wet Wipes Production Lines

Quality control is an indispensable part of wet wipes production. Traditional quality checks, which rely on manual sampling, are inefficient and prone to error. AI-driven visual inspection systems have completely revolutionized this aspect.

These systems use high-definition cameras and advanced computer vision algorithms to perform real-time, comprehensive inspections of every single wipe and every package. They can detect minute flaws, such as stains on the non-woven fabric, inconsistent folding, printing errors on the pouch, or sealing defects. The AI algorithm learns to recognize different types of defects and automatically ejects non-conforming products from the production line. This technology not only boosts inspection speed to an unprecedented level but also ensures a zero-defect product quality, greatly enhancing consumer confidence.

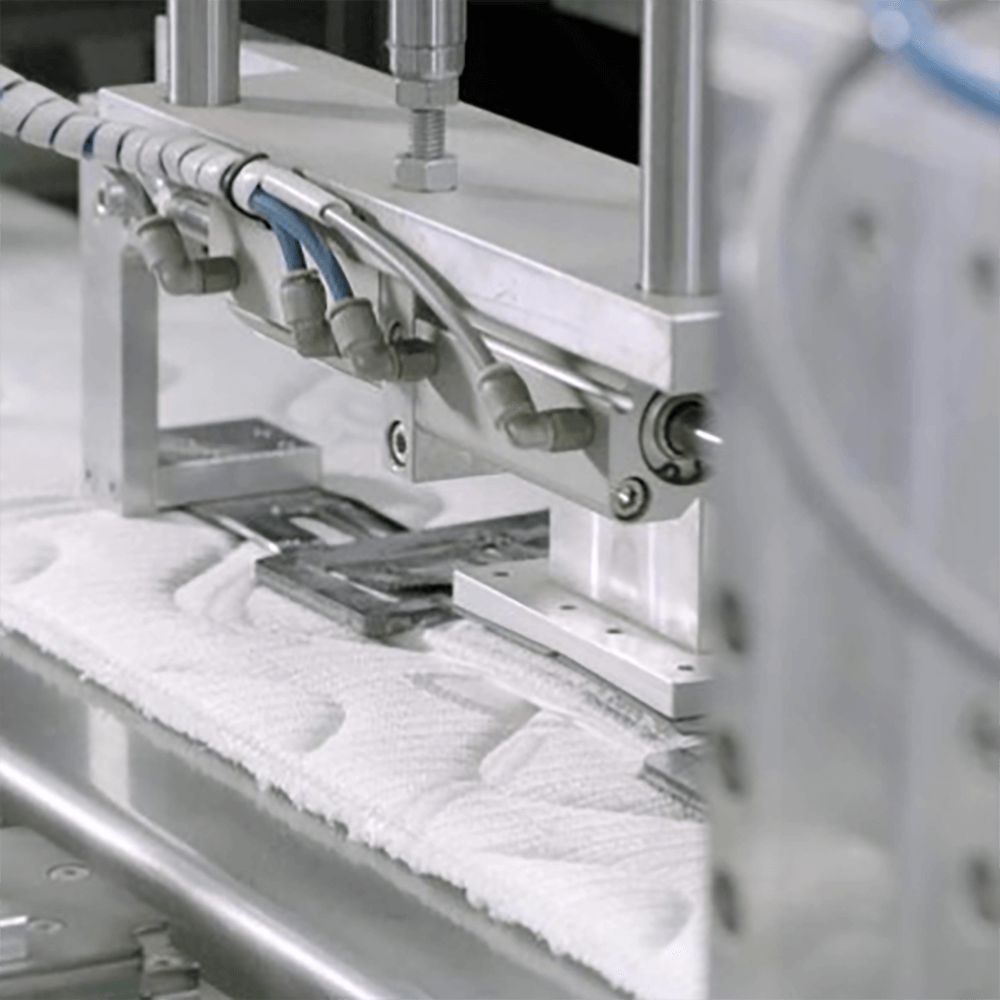

Precision Hot Melt Application Systems for Reliable Lid Sealing in Wet Wipes Containers

In the production of packaged wet wipes in tubs or containers, the quality of the lid’s seal directly impacts the product’s shelf life and user experience. A precision hot melt application system is key to achieving a reliable seal.

This system precisely controls the temperature, flow rate, and application position of the hot melt adhesive, ensuring a strong and long-lasting barrier is formed between the lid and the packaging film. The fast-curing nature of hot melt adhesive allows the production line to operate at high speeds, while its excellent adhesion effectively prevents moisture loss. Modern hot melt systems also feature low maintenance and high precision, allowing for flexible adjustments to accommodate various packaging designs and materials, ensuring every product has a perfect seal.

Cost Optimization Strategies for High-Volume Wet Wipes Production Facilities

In high-volume wet wipes production, cost control is a critical factor in determining a company’s competitiveness. By implementing a range of cost optimization strategies, companies can increase profitability while maintaining quality.

These strategies include, but are not limited to:

- Optimizing Raw Material Procurement: Establishing long-term relationships with suppliers for bulk purchases at lower prices and exploring more economical but equally effective alternative materials.

- Improving Energy Efficiency: Investing in energy-saving equipment and optimizing production processes to reduce energy consumption.

- Controlling Waste Rate: Minimizing the reject rate through automation and quality inspection systems to reduce material waste.

- Labor Management: Reducing reliance on high-intensity, repetitive manual labor through automation and reallocating human resources to more valuable maintenance and management tasks.

Designing Flexible Packaging Solutions for Varied Wet Wipes Product Lines

The market demand for wet wipes is becoming increasingly diverse, ranging from personal care to household cleaning, and from single-pack to bulk-pack formats. This requires packaging solutions to have a high degree of flexibility.

Flexible packaging technology allows manufacturers to quickly switch between different sizes, shapes, and designs on the same production line. This is typically achieved through adjustable bag formers, modular sealing, and cutting units. Flexible packaging also supports a variety of printing and visual effects, enabling brands to attract different consumer demographics with unique packaging designs. This flexibility not only reduces equipment investment but also allows companies to respond quickly to market changes and launch new products.

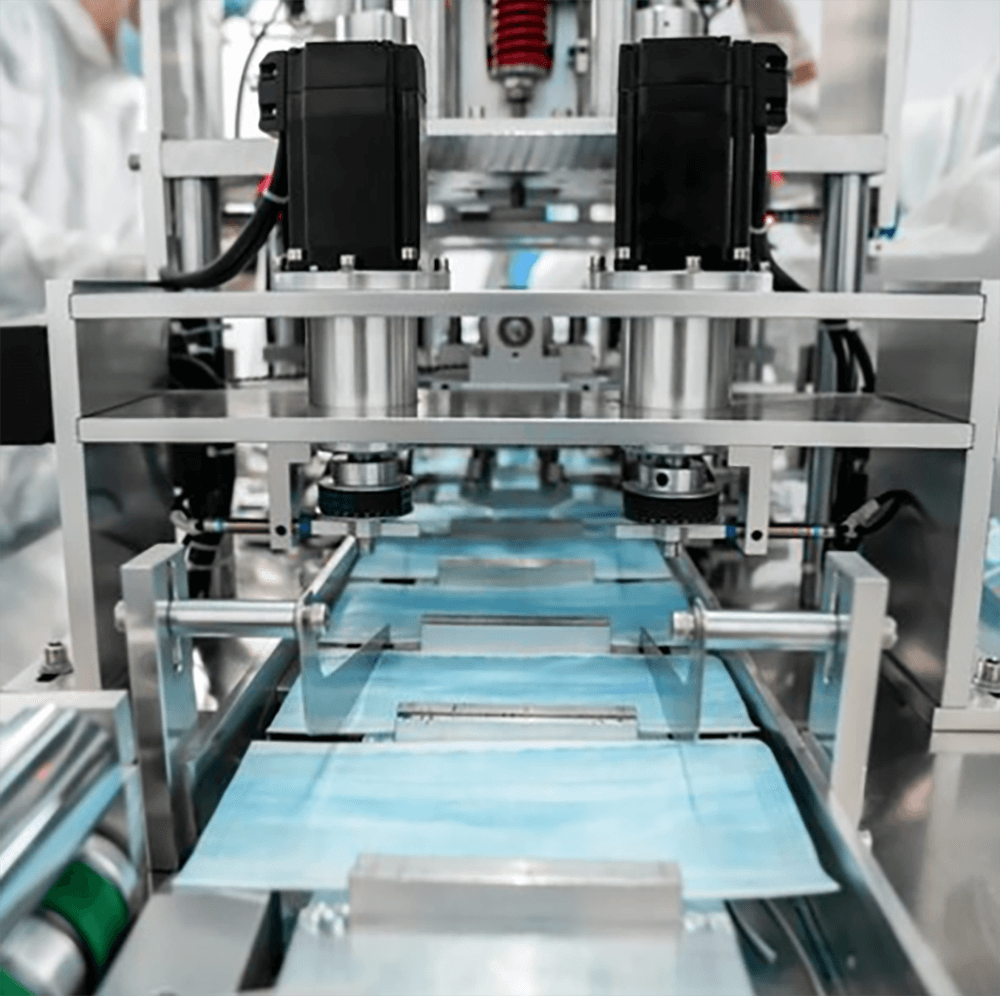

Ultrasonic Sealing Applications in Modern Wet Wipes Flow Wrapping

Traditional packaging seals often rely on heat sealing, which uses heat to melt and bond the packaging film. However, ultrasonic sealing, as an emerging technology, is gaining favor in the wet wipes packaging industry.

Ultrasonic sealing uses high-frequency vibrations to generate heat at the contact points of the packaging film, achieving molecular-level fusion. The advantages of this technology include:

- Energy Efficiency: Ultrasonic sealing does not require prolonged heating, consuming far less energy than heat sealing.

- High Speed: The sealing time is extremely short, which can significantly increase production speed.

- High Quality: The seals are strong and aesthetically pleasing, without damaging heat-sensitive materials.

- Environmentally Friendly: It produces no waste heat, making for a more comfortable working environment.

End-of-Line Automation Solutions: Advanced Robotic Systems for Wet Wipes Case Packing

At the end of the production line, packing finished wet wipes into cases or onto pallets was once a time-consuming and repetitive task. Today, advanced robotic systems have taken over this job.

These robots are equipped with precise grasping tools and vision-guided systems, enabling them to accurately identify wet wipes packages of various sizes and shapes and stack them according to a preset pattern for case packing or palletizing. Robotic systems can work around the clock, with speed and accuracy far exceeding manual labor. By integrating robotic technology, wet wipes manufacturers can not only significantly improve end-of-line efficiency but also reduce product damage caused by improper manual handling, ultimately achieving complete automation from raw materials to finished goods.