The term “lamination” commonly used in the industry actually refers to “layering,” which involves bonding films of different properties together using specific methods, followed by sealing to protect the contents. The primary lamination processing methods for flexible packaging include dry lamination, wet lamination, extrusion lamination, and co-extrusion lamination.

1. Dry Lamination

Dry lamination is the most traditional and widely used lamination technology in China, extensively applied in the packaging of food, pharmaceuticals, cosmetics, daily necessities, light industrial products, chemicals, electronic products, and more. Dry lamination involves applying a layer of solvent-based adhesive to a plastic film using a coating device (typically a gravure screen roller coating system), then removing the solvent and drying the film using a laminating machine. The film is then laminated with other substrates, such as other films, aluminum foil, etc., to form a composite film. The process flow is shown in the figure below. Since it is laminated in the “dry” state of the adhesive (solvent-free state), it is called dry lamination.

Dry lamination is suitable for various composite film substrates and for bonding film with aluminum foil or paper, offering a wide range of applications. It exhibits excellent resistance to chemical medium corrosion, such as alkaline, acidic, spicy, or oily components in food; water, fragrances, or emulsifiers in cosmetics; or solvents and pesticides in chemicals. It is widely used in packaging with stringent content conditions. It features high composite strength, good stability, and high product transparency, enabling the production of both high- and medium-grade composite films, as well as frozen, fresh-keeping, or high-temperature sterilized composite films. It is convenient and flexible to use, with simple operation, making it suitable for production of multiple varieties in small batches.

However, dry lamination also has drawbacks such as poor safety and hygiene, environmental pollution, and higher costs. The development of alcohol-soluble and water-soluble adhesives has to some extent alleviated the pressure on solvent-based adhesives in terms of safety, hygiene, environmental pollution, and cost. Dry lamination still accounts for a significant proportion of composite material processing methods and remains an irreplaceable composite processing method at present, which cannot be replaced by extrusion lamination, wet lamination, or solvent-free lamination methods.

2. Wet Laminating

Wet laminating involves coating a layer of adhesive on the surface of the composite substrate (plastic film, aluminum foil), then laminating it with other materials (paper, cellophane) using a pressure roller while the adhesive is still wet, followed by drying in a heat tunnel to form a composite film. The characteristics of wet laminating include simple process operations, low adhesive usage, low cost, and fast laminating speed. The adhesives used in wet lamination primarily include polyvinyl alcohol, sodium silicate, starch, polyvinyl acetate, ethylene-vinyl acetate copolymer, polyacrylate, and natural resins. The working principle of a wet composite machine is similar to that of a dry composite machine, with the difference being that in dry composite, the adhesive-coated film is heated in a drying tunnel until the organic solvents in the adhesive evaporate, then the composite material is thermally bonded; whereas in wet composite, the adhesive-coated film is directly laminated with the composite material, then enters the drying tunnel for drying.

When using wet lamination, at least one of the two base materials must be a porous material (such as paper or cardboard) to allow the diluents in the adhesive to evaporate during drying. Therefore, wet lamination is widely used for laminating materials such as paper/fiber, paper/paper, paper/cardboard, and paper/aluminum foil.

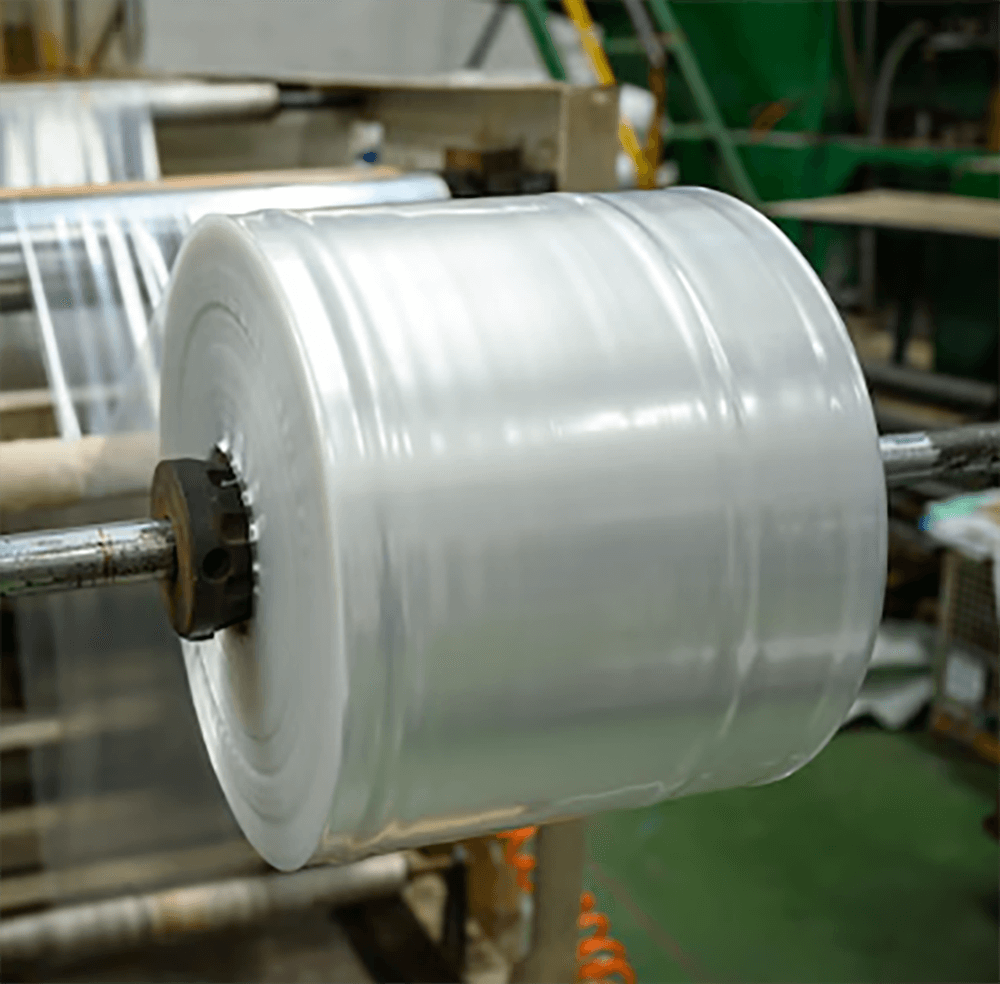

Extrusion lamination involves melting thermoplastic materials such as polyethylene in an extruder, then extruding them through a flat die to form a flat film. This film is immediately laminated with another film or two films using cooling rolls and lamination rolls. Compared to other lamination methods, extrusion lamination offers advantages such as low equipment costs, minimal investment, a clean production environment, no residual solvents in the laminated film, high production efficiency, and ease of operation. Extrusion lamination plays a significant role in plastic lamination processing. Extrusion laminated films can be produced using either extrusion coating or extrusion lamination methods.

3. Extrusion Coating Film

Extrusion coating involves melting thermoplastic materials such as polyethylene, extruding them through a flat die head, and pressing them between two closely contacting rollers onto another substrate. After cooling, this process produces a composite film.

The unwound substrate is typically pre-printed materials such as PET, BOPP, or paper. For example, instant noodle packaging bags are a typical example of extrusion coating production, with a structure of: BOPP printed film / LDPE (or PP).

4. Extrusion-Composite Film

Extrusion composite involves sandwiching extruded resin between two substrates, where it acts as an adhesive to bond the two substrates together while also serving as a composite layer.

The first substrate is often PET, BOPP, PA, paper, etc., while the second substrate is typically LDPE, CPP, aluminum foil, or aluminum-coated film. The extruded resin is usually PE, PP, EVA, EAA, etc. This method is commonly used for ordinary laundry detergent packaging films, with the following structure: BOPP printed film / extruded resin / PE film.

5. Solvent-free lamination

The adhesive used in solvent-free lamination is gaining attention due to its lack of organic solvents. In developed countries such as Europe and the United States, solvent-free lamination has become the primary method for producing flexible packaging composite materials. This method involves coating the base material with a solvent-free adhesive and directly bonding it to a second base material. Although it uses adhesive like dry lamination, the adhesive contains no organic solvents and does not require a drying unit.

Due to its superior environmental friendliness and product performance comparable to dry lamination, it represents the future direction of development.

6. Co-extrusion lamination

Co-extrusion lamination is a forming method for producing composite films by using two or more extruders to melt and plasticize different types of plastics, then feeding them into a die or combining them through a distributor before feeding them into the die. The different plastics referred to here can be of different types, or of the same type but different grades, or of the same grade but different formulations.

Co-extrusion lamination has lower costs, reducing expenses by 20%-30% compared to dry lamination. Additionally, the co-extrusion lamination process does not use adhesives or anchor coating agents (AC agents), resulting in better hygiene and no environmental pollution issues. However, it is significantly limited by material constraints. Composite films produced using the co-extrusion composite process are limited to various thermoplastic plastics. If composite materials containing aluminum foil, paper, etc., are required, the co-extrusion composite method cannot be used for production. Additionally, printing cannot be performed between composite films. When printing is required on the film, patterns, text, etc., can only be printed on the surface of the composite film.