Slider Pouches Solution Provider

The most substantial positive effect we can have on the environment is by minimizing the materials we produce and utilize. Slider pouches achieves this by offering maximum product with minimal packaging. It lowers energy consumption during production and transportation, reduces packaging waste, and enhances product protection effectively.

What Is Slider Pouches

- Pouch Body: Usually made of flexible materials such as plastic films (like polyethylene, polypropylene), laminated films (combining different layers for enhanced properties like barrier protection), or sometimes paper – based materials. These materials offer durability, flexibility, and can be customized with different colors and prints.

- Slider Closure: The most distinctive feature is the slider, which is a small, often plastic – made device that runs along a zipper – like track on the pouch. The slider allows for easy opening and closing of the pouch, creating a tight seal when closed to keep the contents inside fresh and protected.

- Stand – Up Pouches: These have a flat bottom that allows them to stand upright on store shelves or countertops. They are commonly used for products like food items, cosmetics, and household cleaners. The slider is usually located at the top of the pouch, providing easy access to the contents.

- Flat Pouches: As the name suggests, these are flat – shaped pouches that are often used for packaging thin or flat items such as small electronic components, stationery, or some types of food products like dried fruits or candies that don’t require a lot of space. The slider can be placed on the top or side of the pouch depending on the design and intended use.

Key Features Of Slider Pouches

- Reclosable Design: The slider closure allows for easy opening and closing of the pouch multiple times. This feature is extremely convenient for consumers, as it enables them to access the contents of the pouch as needed while keeping the remaining items fresh and protected when not in use.

- Excellent Sealability: The zipper – like mechanism of the slider creates a tight seal, effectively preventing air, moisture, and other contaminants from entering the pouch. This helps to maintain the quality and freshness of the packaged products, extending their shelf life.

- Versatile Sizes and Shapes: Slider pouches come in a wide range of sizes and shapes to accommodate different products and packaging requirements. They can be small and flat for single – serve items or large and stand – up for bulkier products, offering flexibility in packaging design.

- Transparency Options: Many slider pouches are made from clear materials, allowing consumers to easily see the contents inside. This transparency is beneficial for product visibility and marketing, as it enables customers to identify the product without having to open the pouch.

- Durable and Flexible: The materials used to make slider pouches are typically strong and durable, able to withstand handling, storage, and transportation without tearing or breaking. At the same time, they are often flexible, which makes them easy to handle and store, and they can conform to the shape of the contents.

The Application Of Slider Pouches

- Packaging of dry food: They are widely used for packaging snacks like chips, nuts, and crackers. The slider closure ensures that the contents remain fresh by preventing air and moisture from entering. It also allows for easy opening and closing, which is convenient for consumers to access the food multiple times.

- Storage of baked goods: Items such as cookies, biscuits, and bread can be stored in slider pouches. The pouches help maintain the texture and flavor of the baked goods by protecting them from external factors that could cause spoilage or staleness.

- Packaging of frozen food: Many frozen food products, such as frozen fruits, vegetables, and prepared meals, are packaged in slider pouches. The pouches provide a secure seal to prevent freezer burn and keep the food in good condition during storage and transportation.

- Packaging of detergents: Laundry detergents and dishwashing detergents are sometimes packaged in slider pouches. The pouches are designed to be durable and leak – proof, and the slider closure allows for easy pouring and storage. Some pouches may also have features like measuring cups or spouts to make it easier for consumers to use the right amount of detergent.

- Packaging of cleaning agents: Pouches are used to package various cleaning agents, such as all – purpose cleaners, window cleaners, and disinfectants. The slider closure helps prevent the cleaners from spilling and allows for easy access when needed. The pouches can be stored in a convenient location in the house and are easy to handle and use.

Contact us to discuss your slider pouches solutions!

We’d like to bring value and save cost for your slider pouches.

Types Of Pouches

Stand Up Pouch

Spouted Pouch

Valve Pouch

3-side Seal Pouch

Special Shape Pouch

Zipper pouch

8-side Seal pouch

4-side Seal Pouch

Are You Looking For Customized Film Packaging?

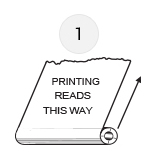

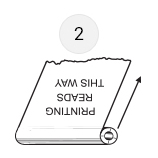

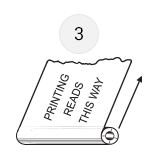

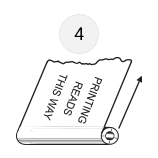

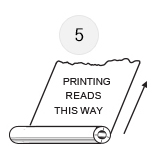

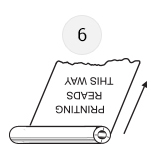

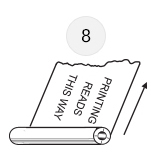

Rollstock Unwind Direction Chart

The unwind direction is a crucial decision for any printed flexible packaging roll stock application. It specifies the direction or orientation in which you want the printed material to be unwound from the roll when it is placed on your equipment. Rollstock can be configured to unwind in total 8 different directions below.

#1

#2

#3

#4

#5

#6

#7

#8

Common Materials Used For Slider Pouches and Their Properties

Aluminum Foil

Aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, which helps maintain food quality and freshness. It is lightweight, easy to process, and recyclable, making it suitable for various food packaging applications.

Nylon (Polyamide)

Nylon possesses good mechanical strength and abrasion resistance, along with high barrier performance. It is suitable for food packaging that requires resistance to high temperatures and freezing, effectively extending the shelf life of products.

Polyester (PET)

Polyester materials have high transparency and excellent optical properties along with good barrier performance. They are commonly used in beverage bottles and other packaging, providing resistance against moisture and oxygen ingress.

Ethylene-Vinyl Alcohol Copolymer (EVOH)

BOPP (Biaxially Oriented Polypropylene)

CPP (Cast Polypropylene)

Kraft Paper

Polyethylene (PE)

Bioplastics

Frequently Asked Questions

About slider pouches

You are welcome to contact us for any questions unclear or interested, we are open to exchange ideas about this slider pouches makret with you.

1. What material are these slider pouches made of?

Answer: Our slider pouches are mainly made of polyethylene (PE), polypropylene (PP), or their composite materials. These materials have good flexibility, strength, and barrier properties, effectively protecting your products.

2. Is the zipper on the slider pouch strong? Can it withstand multiple openings and closings?

Answer: Yes, the zippers we use have been rigorously tested and are highly durable. They can easily withstand thousands of opening and closing operations, ensuring excellent sealing performance over long – term use.

3. Can the size of the pouch be customized?

Answer: Certainly. We can customize slider pouches of various specifications according to your product size and packaging requirements to ensure a perfect fit for your products.

4. Can the pouch be printed on? How about the printing effect?

Answer: Yes. We use advanced printing technologies such as gravure printing and flexographic printing to achieve high – precision and vivid – color printing effects. The pouch has a large printing area, which can clearly display your brand logo, product information, and exquisite patterns.

5. How about the sealing performance of the pouch?

Answer: The zipper design of the slider pouch can form a tight seal, effectively preventing air, moisture, and dust from entering. Each batch of pouches will undergo strict sealing performance testing to ensure no leakage and provide reliable protection for your products.

6. Is this type of pouch environmentally friendly?

Answer: We offer a variety of environmentally friendly options, such as slider pouches made of biodegradable materials. These pouches can gradually decompose in the natural environment, reducing environmental pollution. You can choose the appropriate material according to your environmental protection needs.

7. Will the pouches be damaged during transportation?

Answer: We have rich experience in packaging and transportation. Before delivery, the pouches will be properly packaged and protected with cushioning materials to prevent collisions and squeezes during transportation. At the same time, we cooperate with reliable logistics partners to reduce the risk of damage during transportation.

8. Can samples be provided?

Answer: Yes. We are happy to provide samples for you to evaluate the quality, size, printing effect, etc. of the pouch. You just need to apply to us and pay a certain sample fee (which can be deducted from the payment for the subsequent order), and we will arrange to send the samples to you as soon as possible.

9. What is the maximum weight the pouch can bear?

10. Can special designs such as handles or hanging holes be added to the pouch?

11. How about the transparency of the pouch?

Answer: We offer pouches with different levels of transparency. If you want the product to be clearly displayed, we have high – transparency materials for you to choose from; if you need a certain degree of light – shielding, there are also translucent or opaque materials to meet your needs.

12. How is the price calculated?

Answer: The price mainly depends on factors such as pouch size, material, printing requirements, and order quantity. The larger the size, the more special the material, the more complex the printing, and the smaller the order quantity, the relatively higher the price. We will provide you with a detailed quotation according to your specific requirements.

13. What are the payment methods?

Answer: We usually accept payment methods such as telegraphic transfer (T/T) and letter of credit (L/C). The specific payment method can be determined according to your needs and negotiation between both parties.

14. How to ensure that the quality of the pouch meets the standards?

Answer: We have a strict quality control system. From raw material procurement, production process to finished product inspection, each link is strictly controlled in accordance with relevant quality standards. All products will undergo multiple quality inspections before leaving the factory to ensure compliance with your requirements and industry standards.

15. Do you have relevant certifications?

Answer: Yes, our production process complies with a number of international and domestic standards and has certifications such as ISO quality management system certification and food – contact material safety certification. These certifications prove the quality and safety of our products, and you can purchase with confidence.

16. What is the return and exchange policy if I am not satisfied with the received pouches?

Frequently Asked Questions

About Flexible Packaging

What types of flexible packaging do you offer?

What materials are used in your flexible packaging?

Can you provide custom printing on the packaging?

Do you offer samples before placing a bulk order?

What barrier properties do your flexible packages have?

What quality control measures do you have in place?

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.

WhatsApp: +86-15057184967

Email: [email protected]