Customized Printed PE-coated Paper Roll Supplier

Printed PE Coated Paper Roll Manufacturer

Noupack specializes in delivering high-quality, customizable packaging solutions for a wide range of industries. Our products offer excellent moisture and grease resistance, ensuring superior protection for your goods. With advanced printing capabilities, we provide vibrant, detailed branding to meet your specific needs. Eco-friendly options are also available.

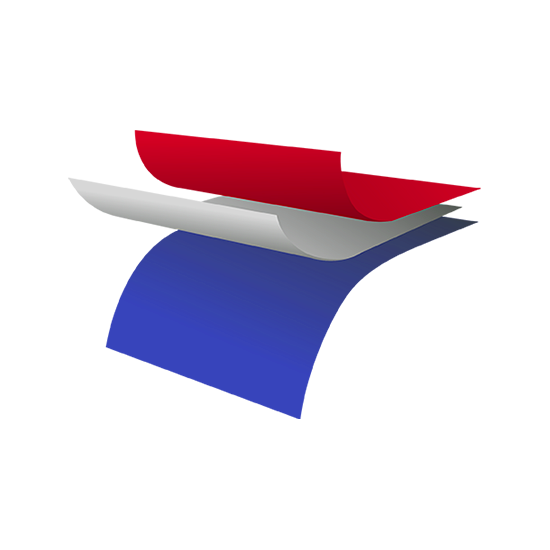

Common Structures Of PE Coated Paper Rolls

1. Single-Side PE-Coated Paper

- Structure: This type features a polyethylene (PE) coating on one side of the paper, providing water resistance. It is commonly used for packaging snacks, baked goods, and fast food items.

2. Double-Side PE-Coated Paper

- Structure: Coated with PE on both sides, this paper offers enhanced moisture and grease resistance. It is ideal for packaging frozen foods, meats, and seafood, ensuring durability and protection from contaminants.

3. Sandwich PE-Coated Paper

- Structure: This consists of a layer of PE coating sandwiched between two layers of paper, making it highly water-resistant. It is commonly used for packaging sandwiches and burgers.

4.Biodegradable PE-Coated Paper

- Structure: Eco-friendly options incorporate biodegradable materials alongside traditional PE coatings to reduce environmental impact while maintaining functionality.

About Custom Printing PE Coated Paper Roll

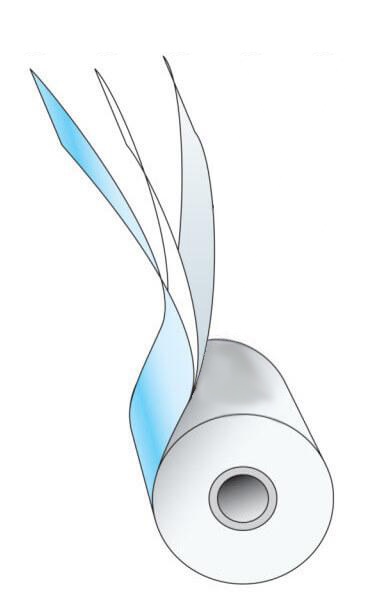

Printed PE (Polyethylene) Coated Film Roll is a type of flexible packaging material that consists of a plastic film, typically made from polyethylene, which has been coated with an additional layer of PE to enhance its strength, moisture resistance, and barrier properties. This film is also printed with designs, branding, or product information to serve as the exterior packaging for various products.

Common Structures:

Two-Layer: Total two layers of PE laminated paper film with customized printed designs.

Multi-Layer (Laminated): Combines different layers (e.g., PE, Papar, PET) to provide enhanced barrier properties and durability.

Key Features of Printed PE Coated Paper Roll

Polyethylene (PE) Coating: Polyethylene is a lightweight, durable plastic that provides excellent moisture resistance. The PE coating enhances the protective properties of the base film, making it more resistant to moisture, grease, and other external elements.

Printing: The surface of the film is printed using various techniques, such as gravure or flexographic printing. This allows manufacturers to display brand logos, product information, instructions, and other important details directly on the film.

Flexible Packaging: PE coated film rolls are highly flexible, making them suitable for wrapping or forming into pouches, bags, or other types of packaging. They are commonly used in the food, beverage, pharmaceutical, and consumer goods industries.

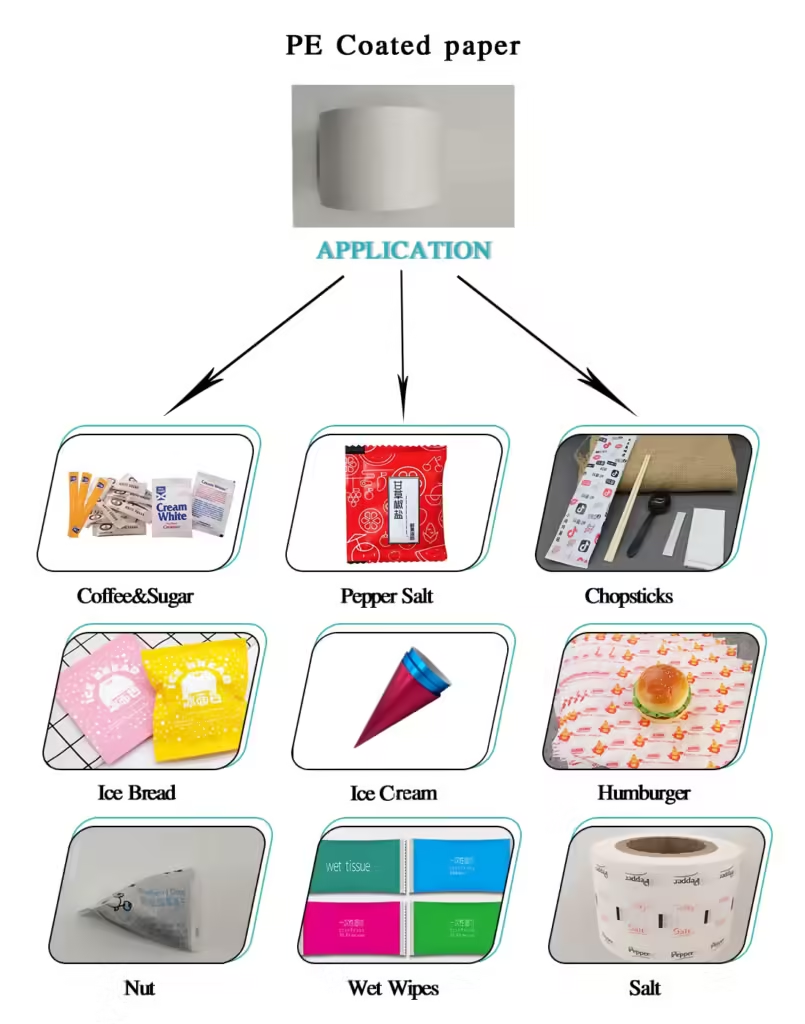

Applications Of PE Coated Paper Film Roll

1,Food Packaging: Snacks, frozen foods, dairy products, and bakery items often use printed PE coated film for packaging due to its moisture resistance and the ability to print attractive designs.

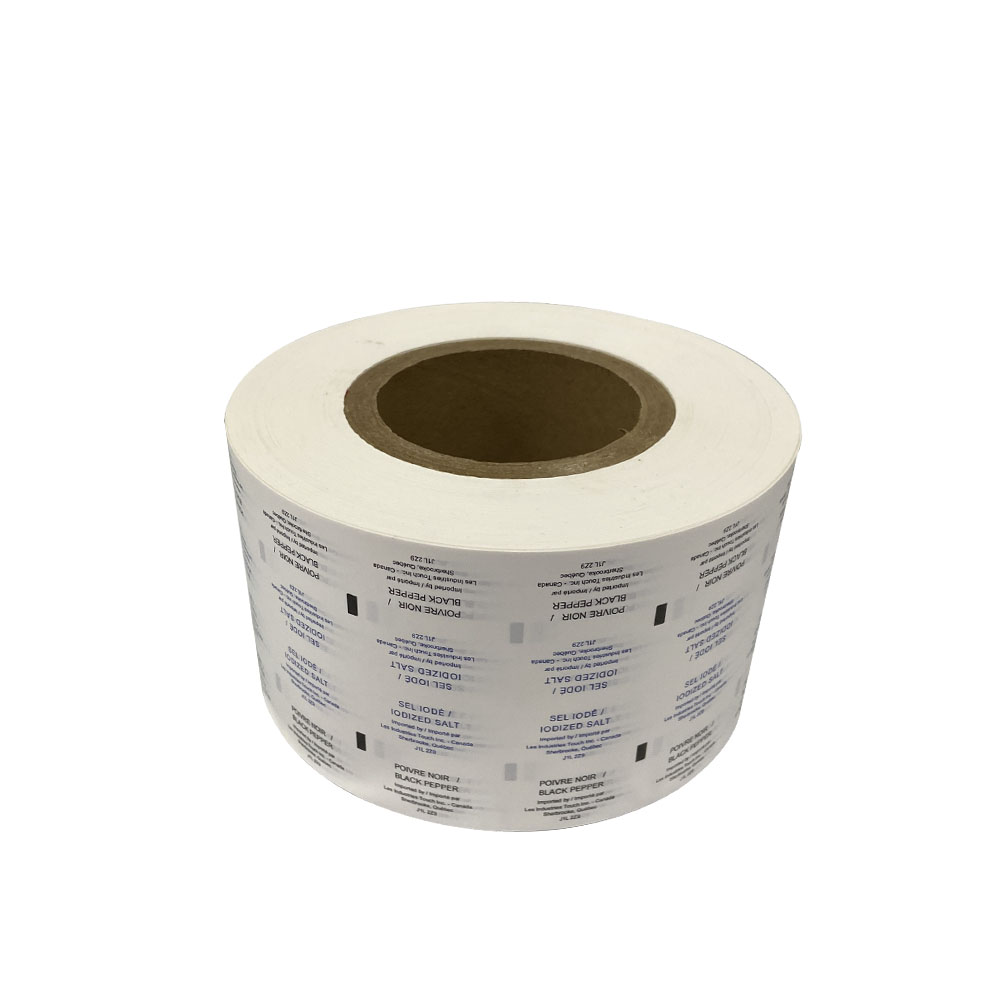

PE Paper Rolls are most commonly used for:

- Sugar stick sachet, salt and pepper sachet packaging.

- Ice cream wrapping paper cone

- Hamburger wrapping paper

- ……

2,Pharmaceutical Packaging: Provides protective barriers for medical supplies while ensuring important product information is clearly visible.

3,Cosmetics and Personal Care: Used for packaging items such as wipes, creams, and other personal care products.

Advantages Of Printed PE Coated Paper Roll

Customizable: Can be printed with any design or branding elements, making it visually appealing and informative.

Cost-effective: Polyethylene is generally inexpensive and widely available, which helps reduce packaging costs.

Versatile: Can be used for various applications depending on the product’s needs (e.g., barrier properties, aesthetics, durability).

Contact Us to Custom Your Flexible Packaging

We’re ready to help you improve your packaging solutions here.

Differences Between Single-sided And Double-sided PE Coated Paper Rolls

1. Coating Application

Single-Sided PE-Coated Paper: This type has a polyethylene (PE) coating applied to one side only. The uncoated side retains the natural properties of the paper, making it suitable for applications where only one side needs protection from moisture or grease.

Double-Sided PE-Coated Paper: This type features a PE coating on both sides, providing enhanced protection against moisture and grease from all angles. This dual coating makes it more versatile for various applications.

2. Barrier Properties

- Single-Sided: Offers water resistance on the coated side, making it suitable for items like snack packaging and fast food wrappers where only one side is exposed to moisture.

- Double-Sided: Provides superior barrier properties, making it ideal for packaging frozen foods, meats, and seafood where both sides need protection from moisture and contamination.

3. Typical Applications

- Single-Sided: Commonly used for food packaging such as paper bags for snacks, bakery items, and takeout containers where the inside does not require a protective layer.

- Double-Sided: Often used in applications requiring higher durability and moisture resistance, such as packaging for frozen meals, meat products, and items that may be exposed to liquids.

Common Materials Used For Printed Foil Paper

Kraft Paper

Known for its strength and durability, kraft paper is often used as the base material for PE-coated paper. It is typically unbleached, providing a natural look.

Low-Density Polyethylene (LDPE)

This thermoplastic material is commonly used for coating due to its excellent moisture and grease resistance. LDPE is flexible and provides a good seal for food packaging.

High-Density Polyethylene (HDPE)

Sometimes used for specific applications requiring higher strength and rigidity compared to LDPE.

Water-Based Inks

Solvent-Based Inks

Additives

Anti-Fog Agents, to prevent condensation on the surface, particularly useful in food packaging where visibility is important. And Slip Agents to reduce friction between layers of coated paper.

Production Process Videos

Stay tuned for our upcoming video series, where we delve deeper into our products and processes, showcasing how Noupack can elevate your brand.

Frequently Asked Questions

About Printed PE Coated Paper Roll

What is the thickness of the PE coating on the paper?

The PE coating thickness typically ranges from 12 to 30 microns, depending on the specific application and requirements. Custom thicknesses are available based on your needs.

Can the PE coated paper rolls be customized with my logo or branding?

What are the available sizes and dimensions of the PE coated paper rolls?

Can your PE coated paper rolls be used for frozen or refrigerated products?

What types of printing methods do you use for customization?

Is the PE coating recyclable or environmentally friendly?

Let's Work Together

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you custom your flexible packaging.

WhatsApp: +86-15057184967

Email: [email protected]